- News

- Reviews

- Bikes

- Accessories

- Accessories - misc

- Computer mounts

- Bags

- Bar ends

- Bike bags & cases

- Bottle cages

- Bottles

- Cameras

- Car racks

- Child seats

- Computers

- Glasses

- GPS units

- Helmets

- Lights - front

- Lights - rear

- Lights - sets

- Locks

- Mirrors

- Mudguards

- Racks

- Pumps & CO2 inflators

- Puncture kits

- Reflectives

- Smart watches

- Stands and racks

- Trailers

- Clothing

- Components

- Bar tape & grips

- Bottom brackets

- Brake & gear cables

- Brake & STI levers

- Brake pads & spares

- Brakes

- Cassettes & freewheels

- Chains

- Chainsets & chainrings

- Derailleurs - front

- Derailleurs - rear

- Forks

- Gear levers & shifters

- Groupsets

- Handlebars & extensions

- Headsets

- Hubs

- Inner tubes

- Pedals

- Quick releases & skewers

- Saddles

- Seatposts

- Stems

- Wheels

- Tyres

- Health, fitness and nutrition

- Tools and workshop

- Miscellaneous

- Cross country mountain bikes

- Tubeless valves

- Buyers Guides

- Features

- Forum

- Recommends

- Podcast

TECH NEWS

Fizik_Adaptive_REGULAR_top

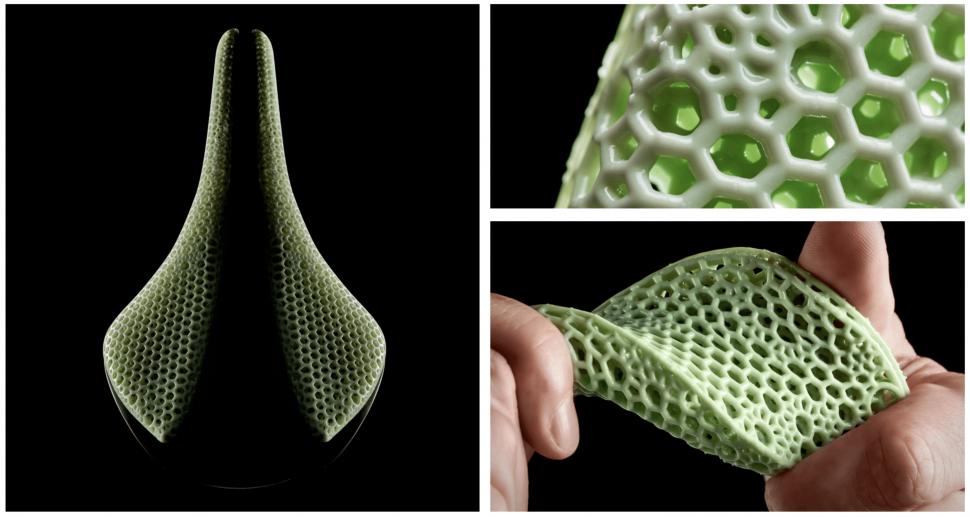

Fizik_Adaptive_REGULAR_topFizik does 3D printed saddles with new Adaptive range

Specialized isn’t the only company investing in 3D printed saddle, Italian brand Fizik has today unveiled its first saddle which has also been manufactured by Carbon, the same Silicon Valley-based company that Spesh partnered with.

Fizik has partnered with Carbon to create a saddle using the same Carbon Digital Light Synthesis (DLS) technology that uses a “digital ultraviolet light projection, oxygen-permeable optics, and programmable liquid resins to produce parts with excellent mechanical properties, resolution and surface finish.”

It basically amounts to 3D printing a special polymer material to replace the usual foam padding used in saddles. The benefit is that the printing process provides the opportunity to do things you can’t with current foam technology constraints.

Fizik is claiming it provides improved power transfer, shock absorption, stability and comfort. Like the Specialized saddle, a lattice is created that is then held in place by a carbon fibre base. It’s quite a different interpretation of the technology to the Specialized saddle which appears to be entirely 3D printed; Fizik has just used it for the top of the saddle.

The unique process will be used first in the Versus Evo 00 saddle, integrated into a full carbon fibre base to keep the weight as low as possible. It reckons it’ll be available in the next coming months, beating Specialized’s expected delivery of early 2020 for its interoperation of this technology.

“We’re proud to partner with fizik to unlock their unique product vision to push the limits of saddle design,” says Erika Berg, Head of Application Development at Carbon. “fizik used the Carbon Lattice Engine to match optimized response profiles based on rider feedback and create a digitally tuned lattice geometry for the Adaptive - enabling differentiation based on their unique product vision and design.”

This new technology creates all sorts of possibilities, as Luca Mathia Bertoncello, fizik Brand Director, explains: “Digital Light Synthesis unlocks a new era in saddle design and manufacturing, driven by athlete data and agile manufacturing processes. It means we can fully release our creativity – transforming not just what we make, but how we make it, bringing a whole new way of thinking to cycling saddles. Our aim is to provide riders with bespoke performance products tailored to their individual biodynamic data.”

We’ve no idea on pricing yet, or how much these new saddles weigh compared to regular Fizik saddles. The road.cc team over at Eurobike will be taking a closer look so stay tuned for more details.

- Specialized unveils 3D printed saddle that can be custom-tuned for each rider

David worked on the road.cc tech team from 2012-2020. Previously he was editor of Bikemagic.com and before that staff writer at RCUK. He's a seasoned cyclist of all disciplines, from road to mountain biking, touring to cyclo-cross, he only wishes he had time to ride them all. He's mildly competitive, though he'll never admit it, and is a frequent road racer but is too lazy to do really well. He currently resides in the Cotswolds, and you can now find him over on his own YouTube channel David Arthur - Just Ride Bikes.

Latest Comments

- ubercurmudgeon 25 min 25 sec ago

I had three different cyclocross bikes before the marketing departments at various bicycle companies came up with the "gravel" category. All of...

- Sredlums 1 hour 9 min ago

Maybe the UK could try to reach some sort of agreement with the EU over things like international trade and such.

- David9694 1 hour 39 min ago

Cumbria County Council was a 1974 creation, merging the of old County Borough of Carlisle, and counties of Cumberland, and Westmorland - in which...

- Backladder 1 hour 50 min ago

If BC want to insist on barriers then they should have their own stock loaded on a truck that they can rent out to organisers at reasonable cost,...

- Miller 2 hours 21 min ago

Well, there's lifetime bans and there's lifetime bans. Banning an 88 year old don't impress me much.

- Gkam84 5 hours 26 min ago

I think that is why blind eyes have been turned in the UK, internationally aswell, with things like the Redhook crits, there were many licensed...

- mdavidford 6 hours 35 min ago

Ahem - other esporters(?) might be rather surprised to hear that the UCI has taken over their events - I think that would be the Cycling Esports...

- Bungle_52 6 hours 44 min ago

I wonder how he got to the game?

- OldRidgeback 6 hours 46 min ago

You'd need some good wet weather gear for that ride too.

- OnYerBike 9 hours 10 min ago

It seems to me that the most likely explanation is that whoever provided that quote fails to grasp the difference between a "public right of way"...

Add new comment

1 comments

I like that these look very comfy, but I can't get out of my head 'how would you keep it clean?' Will they ship with a cover over the holes?