- News

- Reviews

- Bikes

- Accessories

- Accessories - misc

- Computer mounts

- Bags

- Bar ends

- Bike bags & cases

- Bottle cages

- Bottles

- Cameras

- Car racks

- Child seats

- Computers

- Glasses

- GPS units

- Helmets

- Lights - front

- Lights - rear

- Lights - sets

- Locks

- Mirrors

- Mudguards

- Racks

- Pumps & CO2 inflators

- Puncture kits

- Reflectives

- Smart watches

- Stands and racks

- Trailers

- Clothing

- Components

- Bar tape & grips

- Bottom brackets

- Brake & gear cables

- Brake & STI levers

- Brake pads & spares

- Brakes

- Cassettes & freewheels

- Chains

- Chainsets & chainrings

- Derailleurs - front

- Derailleurs - rear

- Forks

- Gear levers & shifters

- Groupsets

- Handlebars & extensions

- Headsets

- Hubs

- Inner tubes

- Pedals

- Quick releases & skewers

- Saddles

- Seatposts

- Stems

- Wheels

- Tyres

- Health, fitness and nutrition

- Tools and workshop

- Miscellaneous

- Cross country mountain bikes

- Tubeless valves

- Buyers Guides

- Features

- Forum

- Recommends

- Podcast

TECH NEWS

2022-Specialized-Allez-Sprint---roadcc

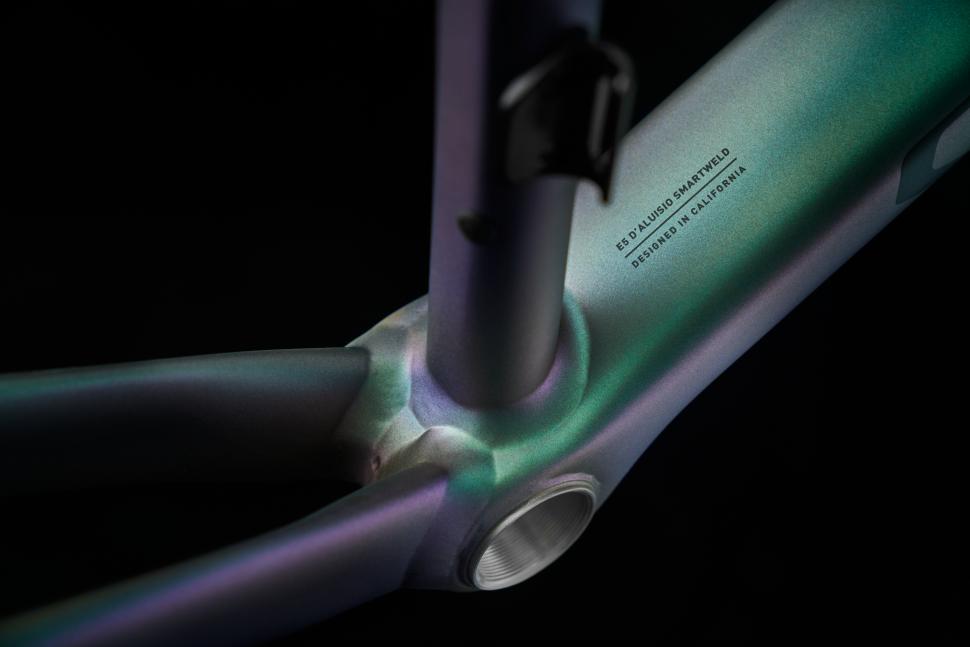

2022-Specialized-Allez-Sprint---roadccThe new Allez Sprint is the ‘world’s first alloy superbike’, claims Specialized

It turns out we didn't have to wait long for a new Specialized Allez Sprint after leaked images surfaced earlier this month... and Specialized has boldly claimed it's the “fastest alloy road bike in history”. Featuring what Specialized says is the most complex alloy headtube it has ever made, integrated cables and tube shapes borrowed from the Tarmac SL7, the brand claims it is 41 seconds faster over 40km than the previous Allez Sprint Disc. The Allez Sprint Comp will also now cost you £2,650.

> Review: Specialized S-Works Tarmac SL7 Dura-Ace Di2 2021

The Allez was the first performance road bike created by Specialized in 1981 - it was a steel racer back in those days. Fast forward to 2013 and we were introduced to the first S-Works Allez featuring D’Aluisio Smartweld technology, and with its new aero tubing in 2015 the Allez Sprint became a performance focused frameset for racers.

And now? The latest updates to the Allez makes it worthy of being called a superbike, Specialized reckons. It turns out many of the things we expected after analysing the leak from Specialized’s Singapore website have made it onto the bike, with the cables all going internal and shapes that borrow heavily from the Tarmac SL7.

“We took every innovation and insight learned developing the Tarmac SL7 and rebuilt it from alloy with our Smartweld technology to create the all-new Allez Sprint,” says Specialized. “Whether chasing a National title or attacking your buddies 15 minutes into an ‘easy’ Sunday spin, we won’t be offended if you mistake the Allez for a Tarmac SL7 - some may call it a carbon copy, we call it the World’s First Alloy Super Bike.”

> 14 best aluminium road bikes — explore this popular material

How has Specialized achieved this?

Specialized says it has developed the most complex head tube it has ever made, which has been cut from a single piece of alloy and then mechanically formed to create a more aero head tube shape with consistent tube wall thickness. “The new headtube process allowed us to move the weld points to take Smartweld to new heights,” says Specialized.

The welds on the Allez Sprint headtube have been moved back, away from the traditional weld points at the tube junctions.

“Moving the welds removed redundant material from the headtube, promoted a uniform result across all the bikes we built, and minimised strain on high-stress areas of the bike, ensuring every rider feels the same stunning ride quality for a lifetime of riding,” Specialized explains.

“We’re still welding in a valley for a stronger, more integrated weld, just doing it in the best possible position to create quality welds that deliver the best ride quality and stand the test of time and road.”

Then there’s the one-piece bottom bracket and downtube, which have been hydroformed from a single piece of alloy. Specialized has removed two weld points from the previous iteration of the Allez Sprint.

> Review: Specialized Allez Sprint Comp 2019

Now with only three welds to the bottom bracket (seat tube and stays), Specialized says it has eliminated unnecessary welds, maximising power transfer and the structural integrity of the frame.

The aero gains of the new Allez Sprint are the result of improvements to the frameset’s tube shaping, Tarmac SL7 fork and seatpost and integrated cable routing which also keeps everything tidy.

As well as improving the aerodynamics and the power transfer efficiency of the Allez Sprint, Specialized says it hasn’t compromised on compliance thanks to the inclusion of the Tarmac SL7’s seatpost and fork, dropped stays and 32mm tyre clearance on 21mm rims with 4mm of clearance. “Of course, this is all still dependent on the exact tyre and rim combination as there is quite a bit of variation among tyres especially,” says Specialized.

“We even poured countless hours into developing new entrance and exit angles for the internally routed cables for smoother shifting."

This bike is designed for racing, and so it also features fit and handling geometry that’s identical to the Tarmac SL7 and the impressively lightweight Aethos.

> Review: Specialized Aethos Pro Ultegra Di2

The Allez Sprint also features Specialized’s first removable front derailleur hanger on an alloy bike for a clean set up for 1x fans. If the front derailleur hanger is removed, a cover for the routing hole and two bolt holes is included.

The Allez Sprint is only compatible with hydraulic disc brakes, but all models can be built with electronic or mechanical drivetrains, 2x or 1x.

Along with its new claimed 'superbike' status, Specialized has massively upped the price. The latest edition of the Allez Sprint Comp costs £2,650. When we tested the Shimano 105 model in 2020 it was just £1,700.

> Ultimate superbikes: the world's most expensive road bikes

Here’s the spec breakdown for the Allez Sprint Comp:

- Frame: Specialized E5 Premium Aluminium Disc frame with D’Aluisio SmartWeld Sprint Technology

- Fork: FACT Carbon

- Groupset: Shimano 105 hydraulic disc

- Chainset: 52/36T

- Cassette: 11-28T

- Bottom bracket: BSA threaded

- Wheels: DT SWISS 470 rim

- Tyres: Specialized Turbo Pro 700x26mm

- Handlebars: Specialized Shallow Drop

- Stem: Specialized 3D-forged alloy, 4-bolt, 7-degree rise

- Saddle: Specialized Power Sport

The Allez Sprint Frameset costs £1,599, and head over to the Specialized website to find our more and see buying options. We've also got one in for review, so check back for some fresh Allez content in the coming weeks.

Anna has been hooked on bikes ever since her youthful beginnings at Hillingdon Cycle Circuit. As an avid road and track racer, she reached the heady heights of a ProCyclingStats profile before leaving for university. Having now completed an MA in Multimedia Journalism, she’s hoping to add some (more successful) results. Although her greatest wish is for the broader acceptance of wearing funky cycling socks over the top of leg warmers.

Latest Comments

- ubercurmudgeon 2 sec ago

I had three different cyclocross bikes before the marketing departments at various bicycle companies came up with the "gravel" category. All of...

- Sredlums 44 min 10 sec ago

Maybe the UK could try to reach some sort of agreement with the EU over things like international trade and such.

- David9694 1 hour 14 min ago

Cumbria County Council was a 1974 creation, merging the of old County Borough of Carlisle, and counties of Cumberland, and Westmorland - in which...

- Backladder 1 hour 25 min ago

If BC want to insist on barriers then they should have their own stock loaded on a truck that they can rent out to organisers at reasonable cost,...

- Miller 1 hour 55 min ago

Well, there's lifetime bans and there's lifetime bans. Banning an 88 year old don't impress me much.

- Gkam84 5 hours 55 sec ago

I think that is why blind eyes have been turned in the UK, internationally aswell, with things like the Redhook crits, there were many licensed...

- mdavidford 6 hours 10 min ago

Ahem - other esporters(?) might be rather surprised to hear that the UCI has taken over their events - I think that would be the Cycling Esports...

- Bungle_52 6 hours 19 min ago

I wonder how he got to the game?

- OldRidgeback 6 hours 21 min ago

You'd need some good wet weather gear for that ride too.

- OnYerBike 8 hours 45 min ago

It seems to me that the most likely explanation is that whoever provided that quote fails to grasp the difference between a "public right of way"...

Add new comment

16 comments

7.9k is not a super bike...

It's an elastic term, obviously, but yes, not even close to the UCI limit, no integrated aero cockpit, no Di2, standard clamp seatpost, very budget wheels...really struggling to see what makes it a "superbike" in any respect.

Presumably the welds are still at the tube junctions, it's just that the tube junctions have been moved back. Or am I being dense?

Depends on how you define the "tubes". Obviously the welds are where one bit of metal joins another bit of metal. But looking at the finished bike, most people would consider the weld to be slightly into the top tube, and not at the (traditional) junction of the top tube/head tube (for example).

I think that if I was in the market for an aluminium bike, I'd be tempted to scour eBay for a Klein that I could restore. At least they knew how to weld back in the day.... Or a Soloist...

God, thoses welds are ugly - it looks like they've used putty or chewing gum, the CaaD13 is no better with its welds - these so called 'big players' need to take a look at some of the bespoke frame builders to see what finished welds should look like.

They're having a laugh. An aluminium bike with 105 for £2,650.....My Caad12 105 with discs was £1,700 about 4-5 years ago.

And having bought a Chisel Expert a few years ago, with DSW, the welds on this Allez look terrible by comparison.

Just looking at a Canyon Endurace AL7 with 105 is £1,700.....I know which one I'd be buying.

That head tube weld is an absolute abomination!!! It's totally ruined the look of the bike. The welds on the Emonda ALR are practically invisible, and a wee company like Mason can make an alu frame look stunning - so why can't a huge company like Specialzed do the same? They're taking the pi$$ with that thing. You’re a mug if you shell out for one of them.

A £1k price rise in 2 years!

Cervelo S1 should be the first aluminium superbike. I still own mine

A thing of beauty, I own one too. Looks better, I have little doubt it's more aero, pretty light and internal cable routing, all achieved 13 years ago !!!!!

I'd like to see a shoot out between this and whatever number the latest CAAD is on.

"...some may call it a carbon copy...". I call that, erm, unalloyed marketing misnomer.

That's a nice looking bike and I'd be happy to ride one. But I'm not sure the £1600 frame price is justified.. when for £1600 I could buy a Giant TCR Advanced Pro frame..

If the Specialized rides better than the Giant, it's entirely justified. Get a test ride on both and judge the bikes by their ride and manufacturing quality, not the material they are created from.

Some of the comments on David Arthur's youtube video about the new model suggest that in this instance the premium price does not necessarily mean premium quality. Caveat emptor.