- News

- Reviews

- Bikes

- Accessories

- Accessories - misc

- Computer mounts

- Bags

- Bar ends

- Bike bags & cases

- Bottle cages

- Bottles

- Cameras

- Car racks

- Child seats

- Computers

- Glasses

- GPS units

- Helmets

- Lights - front

- Lights - rear

- Lights - sets

- Locks

- Mirrors

- Mudguards

- Racks

- Pumps & CO2 inflators

- Puncture kits

- Reflectives

- Smart watches

- Stands and racks

- Trailers

- Clothing

- Components

- Bar tape & grips

- Bottom brackets

- Brake & gear cables

- Brake & STI levers

- Brake pads & spares

- Brakes

- Cassettes & freewheels

- Chains

- Chainsets & chainrings

- Derailleurs - front

- Derailleurs - rear

- Forks

- Gear levers & shifters

- Groupsets

- Handlebars & extensions

- Headsets

- Hubs

- Inner tubes

- Pedals

- Quick releases & skewers

- Saddles

- Seatposts

- Stems

- Wheels

- Tyres

- Health, fitness and nutrition

- Tools and workshop

- Miscellaneous

- Cross country mountain bikes

- Tubeless valves

- Buyers Guides

- Features

- Forum

- Recommends

- Podcast

feature

Museeuw – 2010 bikes and some flax stats

One of the more welcome distractions for bike journalists during the second rest day of the 2007 Tour De France was a press conference by none other than the Lion of Flanders himself, Johann Museeuw.

But the Leeuw wasn't here just to add his support for protégé Tom Boonen's bid for the points competition or speculate whether or not Rasmussen could hold the yellow jersey all the way to Paris.

No, Museeuw was here to introduce a new range of race bikes bearing his name to the Worlds' press. Product launches are 10-a-penny during the Tour, and unfortunately, another big story was breaking on the other side of town; the sending home of race leader Rasmussen by his Rabobank team. Those lucky journos who took the time to attend the Museeuw meeting went away with an unexpected surprise; the scoop on a genuine bike- tech first.

Johann wasn't showing off any old bike either, something sourced in the Far-East and dressed up in go-faster stripes. The Museeuw range was altogether different; here was a bike from a new material, which had been in development for three years before its launch and promised to deliver something other than just marketing spin. What the Tour media circus got was a new word with which to conjure when writing tech reports on the latest in frame materials and technology; flax.

Flax fibre itself is nothing new; it has been around for a long, long time, traditionally found in products as diverse as fine, hand-woven lace and in the rigging of great sailing ships. Flax grows in abundance in the west of Belgium and the north of Ireland. In fact, flax flowers are depicted in the flag of the Northern Irish Assembly and is a feature in coins and banknotes produced by the Province. Flax shares many characteristics with the people of both Flanders and Northern Ireland; hardy stock who flourish despite the harsh climate and even harsher environment.

So it's not surprising Museeuw, the toughest in a long line of tough Flandrian champions, recognised in flax a rugged ability to stand up to whatever the elements could throw at it, and at the same time, capable of producing something of great beauty and finesse - like Museeuw's epic win in the 2000 Paris-Roubaix, a masterclass on how to win a bike race in style .

Facts about flax

Three years on from that eventful July day in Loudenville and Museeuw is preparing to unveil his 2010 range of carbon/flax models to the media and trade at Eurobike. This year Museeuw will be unveiling a whole new range with the flagship MF-One (se the chrome/red model) which is 80% flax content - as high as they can go currently topping it off.

Even more excitingly A 100% flax model is in the works and there should hopefully be a prototype at Eurobike. The rest of the range is rounded out with the 'MC' line; six models with varying flax content to hit a number of price points. For this, they add flax stays, forks or down tubes, depending on the model and price band. They hope to make the flax technology to more accessible to more riders and have added cyclocross and track models. So, what makes bikes made with fllax so special?

Much has been said and written about the properties of flax and whether or not it merits a place on top of the list of exotic materials. But ask anyone who's ever ridden one and they'll all agree; this is a material with properties like no other.

Flax ticks all the boxes in terms of rigidity and low weight, but far from trading off stability, strength and comfort in favour of pandering to the misinformed, it adds a whole new dimension to what is possible when given the right materials to work with.

The Museeuw approach has been to determine how far you can 'ride-tune' a frame through the strategic application of the chosen material. This comes through a thorough study and understanding of how those materials will perform once constructed into a frame. But the most important factor recognised by Museeuw, is that without the expertise to harness and manipulate the potential of the material, the favourable characteristics are lost and inevitably, yet another run-of-the-mill frame is produced.

That's why Museeuw sought out the best when building the team behind his bikes. In much the same way he'd hand-pick riders to support his bid for a World Championship or Classics win, Museeuw has brought together the finest brains in composite technology as well as a team of framebuilders led by legendary Italian framebuilder Roberto Billato, in charge of Museeuw product design one with impeccable credentials backed up by an almost unparalleled list of winners on his client list.

Up until now, the Museeuw philosophy has been to let their product do the talking - in much the same way Johann let his legs do the talking in the Classics.

However, in order to answer the critics who would dismiss the Museeuw range as just another collection of overpriced bikes trading on an ex-racer's past glories, they've commissioned a series of independently-produced reports explaining exactly what it is about the Museeuw flax composite that produces such unique qualities and where the advantage lies when compared to 'ordinary' carbon frames. The findings will be released in full at a press conference held during the trade and press days of Eurobike, but we have has been given and advance 'sneak peek' of the results and can give a brief outline of what all the numbers mean.

Carbon fibre, (like steel or alu or titanium), has common characteristics regardless of the source of the material. In the case of carbon, this is because at microscopic level, the individual strands making up the material all perform in the same way to whatever stresses, strains or vibration you subject them to. It's the vibration that determines that all- important 'feel'. The rider will feel, (to a greater or lesser extent), whatever vibration is transmitted up through the wheels and out along the frame and fork. It's how much the frame transmits of whatever is going on under the tyres determining how much a rider feels in their shorts and through the handlebar tape.

Those vibrations have two significant parameters : amplitude and frequency. The amplitude part is how hard the shock is, while the frequency is how long that shock lasts before it is dissipated. Amplitude is measured in parts of a second, frequency in Hertz, or length of cycle. If you think of it in terms of a bell, the amplitude is the note and the frequency is how long the bell holds that note before fading away.

Carbon weaves consist of woven strands, and in turn, those strands consist of microscopic filaments. Contrary to popular belief, Its only when you get down to filament level the damping occurs. As good as carbon fibre is at being light and strong, it can only dissipate shock in specific frequencies. So some – but not all – of the shock is absorbed. Adding more carbon might appear to be a logical solution for tuning-out vibration, but this usually leads to a frame with the dreaded 'wooden ride' characteristics. Chucking more carbon in the pot is not the answer.

Which leaves the rest of the vibration to be handled by the rider. Absorbing shock is a major energy burner and as a result, the more shocks on the rider, the faster the rider is pushed towards the point of discomfort, followed by the onset of fatigue.

In other words, smooth roads good, rough roads bad.

That said, each and every rider has his or her threshold of pain determining how hard and how long they can ride or race. All riders are subjected to shocks just the same; no one is immune from vibration.

However, ask anyone who's ridden a Museeuw how it 'felt' and they'll all tell you the outstanding characteristic was the smoothness of the ride.

It's right down at the microscopic level the secret of this smoothness lies. Whereas carbon filaments are equal in their ability at handling only a specific range of frequencies, flax filaments all react differently, each filament coping with a different range of frequencies and as a result, damping a far greater range of vibration than carbon - or any other material - can.

The greater the flax content, the more buttery the ride. Not only that, the high-flax content composite, thanks to its superior absorption, will demonstrate far greater road-holding qualities. Here's one scenario; a stiff-wheeled, carbon-framed bike ridden full-tilt over cobbles is likely to act like a bucking bronco, whereas a Museeuw, kitted out with the same wheels and components - but with its flax composite frame – will glide effortlessly and with far greater control, over the bump and grind of Belgian Pavé. That in turn, leads to less physical demands on the rider and increases their ability to stay with the pace.

But without proof, all this is just marketing spin.

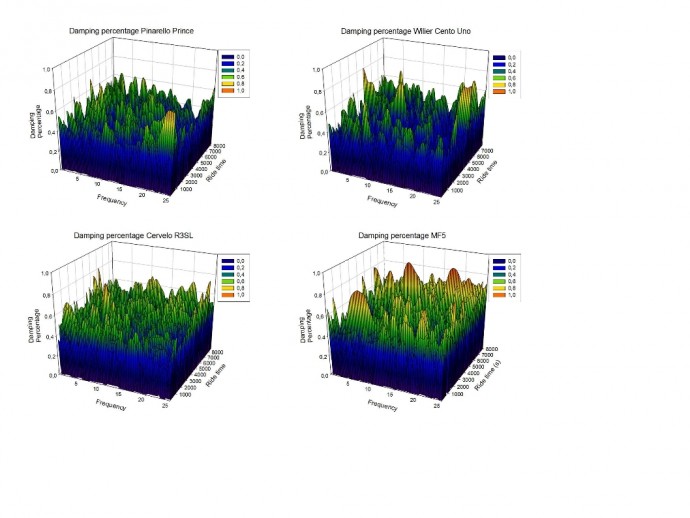

So over the last year, Museeuw, in association with IPA Composites (who make the composite for Museeuw Bikes) and the Engineering faculty of the University of Ghent have been putting a Museeuw MF-5 to the test and analysing data . And not just on a Museeuw bike, but also bikes built around frames used at the highest level and which would undoubtedly feature in the top ten of any 'dream bike' list.

The bikes in question were the Pinarello Prince, (bike of the 2008 UCI World Cup winner), the Cervélo R3SL (Tour de France-winning bike) and the Wilier Cento Uno (World Champ winner).

Stiff competition whatever way you look at it.

Each bike was fitted with five accelerometers at all the key points of the bike that determine ride quality. From these sensors, the collected data was then analysed to produce a map of how each bike performed in terms of damping performance. When the four are stacked up together, its clear from the graphs how well the Museeuw flax-based frame stood up against the competition.

In short, the subjective claims of the many happy Museeuw owners (and those fortunate to have ridden one in tests) are now backed-up with an objective set of results confirming what they've known all along; the Museeuw does offer the smoothest of rides and they are undoubtedly one of the finest performance composite frame available today.

Stay tuned !

Latest Comments

- dubwise 3 sec ago

So cyclists will be punished far heavier than killer drivers. Sums up the fkd up UK.

- HLaB 13 min 15 sec ago

I've done the 312 and other closed roads events like the Etape Caledonia and each time there is bad press like this in advance but on the day the...

- Rendel Harris 13 min 29 sec ago

It's not that surprising that Mr GrumpyGobshite hasn't seen the 20mph limit "stuck too [sic] in 47 years" as it was only reintroduced in 2004, it...

- Pub bike 29 min 8 sec ago

Spiral wound cables can expand and contract and possibly help with brake modulation, as well as make tighter bends. ...

- Burnsy Bhoy 1 hour 50 min ago

My TL200 rear light stopped working after 14 months - it seems IP ratings arent what they say on the tin! I have tried different brands and all...

- OnYerBike 8 hours 1 min ago

I've no idea what the situation is here, but I've seen plenty of "under construction" cycle lanes where there are only signs/barriers around the...

- the little onion 8 hours 8 min ago

whereas the whole point is that they didn't hit you this time

- Tom_77 8 hours 22 min ago

AIUI an entering-circulating accident [sic] would be when the vehicle entering the roundabout fails to give way to the vehicle circulating.

- chrisonabike 8 hours 40 min ago

Which is great - but you can only take a bus which exists eg. is going somewhere near where you want to go, when you want to go....

- mdavidford 10 hours 32 min ago

Erm, does someone need counting lessons?

Add new comment

10 comments

Good spot on the BB cat1commuter - I wasn't sure so I asked. Here's what Roberto Bilato had to say:

"BB 30 is a standard for MF1 - MF5 - MC2 - MC6 - MC TT with adaptor for BSA

threaded .

Std BSA threaded is for MF3 - MF Pista - MC Cross

MF1 - MF5 - MC2 1"1/8 top 1"1/4 bottom integrated head set

MC6 1"1/8 top 1"1/2 bottom integrated head set

ISP ( Integrated seat tube ) for MF1 - MC2 ( aero profile) - MC6

ciao

Roberto Billato

Product Manager"

would a carrot-fibre bike improve my ability at bunny-hopping drain-covers?

Anyway, I'm sure that they are lovely bikes.

Is that a BB30 shell I can see in the closeup of the MC-6 bottom bracket area?

Short answer to that is yes, although I'm not sure by how much - I think the resin is itself pretty hazardous stuff and that would be in a carbon or a flax frame. CF frames are notifiable waste it's an offence to simply throw one away and I think that under EU law the manufacturers need an end user certificate and have to come up with a way of disposing of the frames… one has already designed a range of carbon fibre furniture for cruise ships which will be made from the ground up remains of their old carbon frames.

Not sure about the reflective properties of carrot fibre bikes, but I can say that they will only be available in orange.

excellent ill take two!

is a 'flax' frame more enviromentally friendly than carbon etc..?

and would a carrot fibre bike be reflective in the dark (i.e. carrots make you see in the dark).

It's got to be said, that the guys I know who've tested these bikes (all of whom were sceptical) have all been impressed. It seems to me though that if you want to get the best bike you need to combine the best frame material, built up in the best way, with the best design for optimising performance too - which I'd say has to be the aero race bike, something like the Cervelo S3.

I've not ridden one so I can't pass judgment, and I'm not a good enough rider to take a bike like this to its ultimate limits - that's something that only elites and pros can do, but when you talk to them they will say that it's the sum of all the tiny incrementall advantages a bike and components have, which may in itself only be a very small amount, that give you a performance difference. If everyone is running 28mm at Paris Roubaix then the slight edge a more comfortable but still efficient frame will give you could make the difference. Maybe.

Oh, and flax certainly isn't the most 'out there' of the new frame materials being considered… carrot fibre has been touted as the next big thing for quite a few years now and when you think about it - who' have believed a few years back that one day the Tour de France would be won on a bike made of soot.

They've been around for ages - I'm really surprised that other posters haven't heard about them before...

For a road test review (rather than engineering department graphs) check out Brian Palmer's thoughts:

http://www.thewashingmachinepost.net/museeuw/review.html

Flax- you gotta be kidding! When does the hemp, canvas and muslin range come out?

Well I'm very sceptical about this. The take home message I get from this is "flax fibres are not quite as stiff as carbon". The differences are fractions of a percent (since the span of the vertical axis of each of those graphs is 1% damping).

Running 28 mm tyres instead of 23 mm (which is what they do for Paris-Roubaix) will make a much greater difference.