- News

- Reviews

- Bikes

- Accessories

- Accessories - misc

- Computer mounts

- Bags

- Bar ends

- Bike bags & cases

- Bottle cages

- Bottles

- Cameras

- Car racks

- Child seats

- Computers

- Glasses

- GPS units

- Helmets

- Lights - front

- Lights - rear

- Lights - sets

- Locks

- Mirrors

- Mudguards

- Racks

- Pumps & CO2 inflators

- Puncture kits

- Reflectives

- Smart watches

- Stands and racks

- Trailers

- Clothing

- Components

- Bar tape & grips

- Bottom brackets

- Brake & gear cables

- Brake & STI levers

- Brake pads & spares

- Brakes

- Cassettes & freewheels

- Chains

- Chainsets & chainrings

- Derailleurs - front

- Derailleurs - rear

- Forks

- Gear levers & shifters

- Groupsets

- Handlebars & extensions

- Headsets

- Hubs

- Inner tubes

- Pedals

- Quick releases & skewers

- Saddles

- Seatposts

- Stems

- Wheels

- Tyres

- Health, fitness and nutrition

- Tools and workshop

- Miscellaneous

- Cross country mountain bikes

- Tubeless valves

- Buyers Guides

- Features

- Forum

- Recommends

- Podcast

The science behind keeping your bike clean — we visit Gtechniq's lab to see the latest in ceramic bike care tech

This article includes paid promotion on behalf of Gtechniq

Forget your bucket and washing-up liquid, this is the 21st century. If you really want to keep your bike cleaner for longer, then Gtechniq’s got a far more scientific approach – but how is it different to everything else on the market, and what does a guy in a white coat have to do with it?

Based in Northamptonshire, Gtechniq's HQ is home to some serious lab testing. We got the chance to take a look at the science behind some bike care products, while also finding out a bit more about their hero product, Bike Ceramic.

Whether it’s the dimples on a golf ball or the kind of polish on a Formula 1 car, there is a huge amount of science that goes into the surface of sports equipment. It shouldn’t be particularly surprising, then, to find out that Dr Drew Gill, the founder of detailing brand Gtechniq, has a doctorate in quantum physics.

Rob Earle, Managing Director of Gtechniq, said that it was through Drew's understanding of quantum physics and quantum mechanics that they could understand how to make a surface work correctly, and "produce something that actually delivered the performance that the marketing claims."

The background of Gtechniq isn’t just academic though. What started out as a car maintenance brand over 20 years ago now has an impressive range of vehicle, marine and (the ones most interesting to us) cycling care products.

> Cleaning and protecting your bike is made easy with Gtechniq Ceramic

Why enter the cycling market?

In the car care market, ceramic is now an everyday term. This coating is now commonplace on higher end cars, helping to protect them from scratches, grazing and gritty sponges. The brand has plenty of high-profile partnerships, from hotel fleets of Rolls Royces to Formula 1. It's F1 that led Gtechniq to get involved in bikes.

Gtechniq not only partnered with Racing Point to create coatings that rubber was unable to adhere to, but also another unnamed team whose head of composite engineering happened to be a keen cyclist, and saw an alternative use case for said ceramic coating.

Gtechniq, not being hugely impressed with some of the maintenance lines already out there, saw the benefits that a ceramic coating for bikes could bring, and so set about exploring how they could make bike surfaces perform better.

Earle said: "We just wanted to deliver something that had that level of performance."

> How to clean your bike - from a quick lick to a full makeover

Lee Kennedy, Senior Formulation Chemist at Gtechniq said that "20 years of experience from paint protection in the car world, crosses over massively into the bike world" due to the paint technology on a bike and car being almost identical.

What are the benefits of Gtechniq for cyclists?

Specialising in surface science, Gtechniq wanted to bring high-end technology into the cycling world – but this new range of bike products is far from just a rebadged version of their famed car range.

Ceramic coatings work by making the surfaces hydrophobic, which in simple terms means that water and dirt are less able to stick to them. Then, because hydrophobic surfaces encourage water to bead when you finally get around to giving your pride and glory a good spray down, the muck doesn’t linger.

Kennedy explained that Gtechniq’s Bike Ceramic is a "proper" ceramic coating that chemically bonds to the surface of your bike.

How is bike ceramic different to car products?

Deep in the GTechniq formulation labs, Earle explained to us that the main aim of the Bike Ceramic product is dirt repellency.

Kennedy explained: "We tailored the technology we [already] have, specifically for something that is going to be good at repelling mud and dirt, the sort of contaminants you can get when you ride your bike."

This differs from their car products which have the primary role of scratch and mark resistance, with the extremely thin and hard layer on the surface required so swirl marks aren't shown on the often large, flat panels.

Earle adds: "If you drop your bike, a micron of dirt coating's not really going to do much, so the focus on the bike side was to get the dust repellency and dirt repellency as high as possible so you can spend more time riding and less time cleaning."

Kennedy says: "The cleaning process should be much quicker and easier on a coated bike. "

road.cc are certainly advocates for easier cleaning!

As well as making it easier to clean your bike, Gtechniq created their bike ceramic so that it was easy to apply, meaning anyone can purchase it and apply it directly to their bike.

In the automotive industry, there are many accredited ceramics where you need to be a trained professional to apply them, which simply doesn't make sense for the bike industry.

Therefore, Kennedy says: "We wanted a real DIY product that someone can just clean their bike, apply it, which should be a nice and simple process."

How is Gtechniq different to other bike maintenance brands?

Of course, there are a number of products on the market that promise hydrophobic coatings for your bike – but according to GTechniq, many of them offer nothing more than a surface spray that doesn't last as long and isn’t as effective.

Gtechniq's Bike Ceramic is made from salines, which are silicon compounds that form a bond with the lacquer on a bike's frames or wheels. This makes Gtechniq's treatment far more hard-wearing than a wax or silicon spray product that simply sits on the surface.

Gtechniq have many in-house capabilities with labs and scientists on site. Earle told us that they do a lot of in-house formulating, weathering testing and quality control.

The testing process

Obviously, with these big claims, we were keen to delve a little deeper – so Kennedy offered to take us through the full product development cycle, explaining the science behind the product. Fasten your seatbelts, this gets nerdy!

He starts by explaining that most of their time is spent testing products, with only 5-10% of time spent actually mixing things together.

"One of our more recent products, we tested it over 57,000 times in a 3-year process of continuous testing and there were about 750 real-world assessments," he says.

There is a vigorous repeat testing procedure which includes pushing everything to extremes, so that if there's going to be an issue with the product, it's found here.

One of the ways their bike ceramic coat is tested to gauge durability is in a scrub tester, which physically abrades the surface using a sponge, replicating a contact wash.

Essentially, you're breaking down any coatings on the surface to see how durable it is. After all, the type of people who are interested in ceramic coatings are likely to wash their bikes regularly. It also has the ability to test different strengths of chemicals to help prevent damage to the coating.

Kennedy says that the scrub tester can be run up to 50,000 times with very little sign of degradation.

Another piece of equipment used is the accelerated weathering chamber, which uses UV light to photodegrade the surface of a substrate – essentially this is the sun in a small chamber in the corner of the lab. It allows for years worth of weathering in the space of a few weeks.

Up next we have potentially the most interesting bit of kit in the lab, a tensiometer, which measures surface tension by using water contact angles. In simple terms, this is how far a bead of water will spread on a surface, which can then be used to calculate the surface free energy of a coating.

The aim is for the coating to have a low surface energy, but with hardness, scratch resistance, and durability.

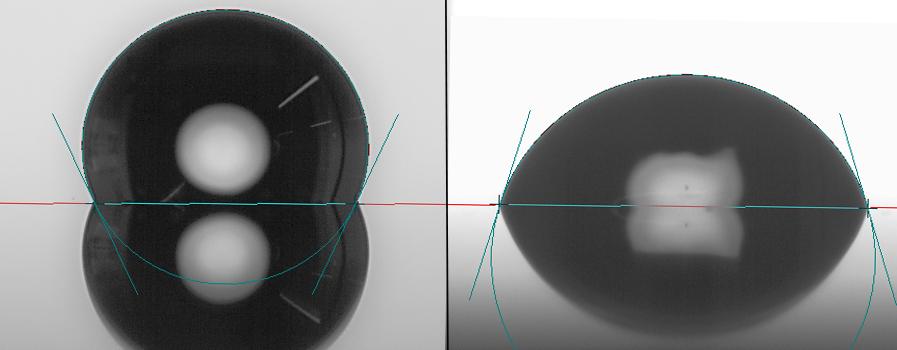

While in the lab, we were able to test two painted plates, one with a ceramic coating applied and one without. Can you guess which one is which? The photo on the left shows how a droplet of water reacts on a panel treated with bike ceramic, and the photo on the right is an untreated panel of standard bike paint.

The bead of water on the untreated panel is much flatter, showing that it wants to spread out onto the surface – however, the droplet on the treated panel (left) is a bead shape where the low surface energy of the plate makes it a much less attractive proposition to stick to.

The same rules of surface energy apply not only to water, but also to any dirt, oil or mud that hits the surface – when riding your bike in poor weather, for example. All of the above want to shy away from the surface, hence it stays cleaner.

Surfaces without a coating cause dirt to be left behind due to water not beading off, which is ultimately harder to clean.

Gtechniq told us that the lowest surface energy you're likely to come across in your day-to-day life is a brand new non-stick frying pan. The ceramic coating that they make comes very close to this figure, but is much much more hard-wearing.

Did you know that this much work went into making bike care products? Let us know in the comments section below...

Emily is our track and road racing specialist, having represented Great Britain at the World and European Track Championships. With a National Title up her sleeve, Emily has just completed her Master’s in Sports Psychology at Loughborough University where she raced for Elite Development Team, Loughborough Lightning.

Emily is our go-to for all things training and when not riding or racing bikes, you can find her online shopping or booking flights…the rest of the office is now considering painting their nails to see if that’s the secret to going fast…

Car flips after crash on Honicknowle Lane in Plymouth...

Interesting to note the points on inability to get GPS lock at times....

Yes, that's what I meant. But Global Nomad is spot-on as well.

They absolutely put their foot in it with that one!

Apparently someone did a study on this......

Funnily enough, I do and police Scotland are useless.

I totally hate the team selection process. So that is it for me with Velogames

Drivers have to drive on the left, and when there is more than one lane (except at junctions) stay in the left lane except when overtaking. There...

DO IT FOR YOOOOOOOORKSHIIIIIRE