- News

- Reviews

- Bikes

- Components

- Bar tape & grips

- Bottom brackets

- Brake & gear cables

- Brake & STI levers

- Brake pads & spares

- Brakes

- Cassettes & freewheels

- Chains

- Chainsets & chainrings

- Derailleurs - front

- Derailleurs - rear

- Forks

- Gear levers & shifters

- Groupsets

- Handlebars & extensions

- Headsets

- Hubs

- Inner tubes

- Pedals

- Quick releases & skewers

- Saddles

- Seatposts

- Stems

- Wheels

- Tyres

- Tubeless valves

- Accessories

- Accessories - misc

- Computer mounts

- Bags

- Bar ends

- Bike bags & cases

- Bottle cages

- Bottles

- Cameras

- Car racks

- Child seats

- Computers

- Glasses

- GPS units

- Helmets

- Lights - front

- Lights - rear

- Lights - sets

- Locks

- Mirrors

- Mudguards

- Racks

- Pumps & CO2 inflators

- Puncture kits

- Reflectives

- Smart watches

- Stands and racks

- Trailers

- Clothing

- Health, fitness and nutrition

- Tools and workshop

- Miscellaneous

- Buyers Guides

- Features

- Forum

- Recommends

- Podcast

TECH NEWS

Huron Cycling Impact chainset 2 - 1

Huron Cycling Impact chainset 2 - 1Patent granted for chainset that “improves cycling efficiency by more than 4%”

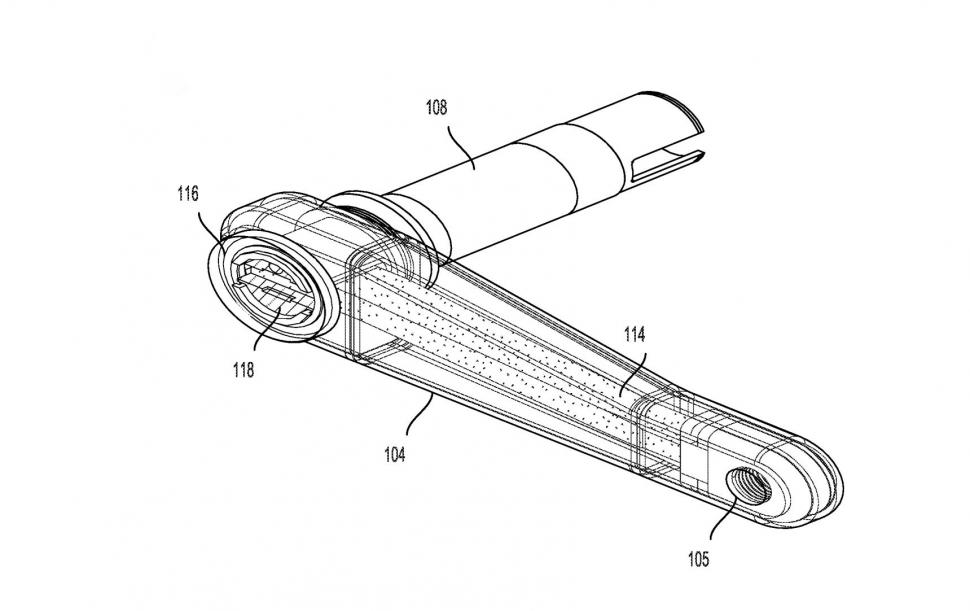

A US patent has been granted for a chainset with a spring action that, according to its inventors, improves cycling efficiency by more than 4%. Huron Cycling says that the spring action in its Impact chainset is comparable to that of the carbon plate used in recent record-breaking running shoes.

“The crank arms are not directly attached to the crank spindle, but can rotate by up to a few degrees,” says Huron Cycling.

“This rotation is counteracted by fibre composite springs inside the hollow crank arms.

“Depending on riding style, the Impact [chainset] improves cycling efficiency, especially when going uphill or accelerating, by reducing the effect of the dead spot during the pedal stroke.”

Although this patent has only just been granted, Huron Cycling has been working on designs that follow similar principles for a few years. You can read the detail on each of them in white papers published on the company’s website.

“The [chainset] stores energy temporarily during the downstroke and releases this energy in the dead spot of the pedal revolution,” says Huron Cycling.

“Both left and right crank contain limited spring action to achieve this goal. Under the load from the cyclist’s efforts the internal springs allow each of the crank arms to rotate by a few degrees relative to the spindle. Deflection at the pedals is up to 20mm and proportional to instantaneous torque. The energy stored in the springs is returned to contribute to torque at the dead spot of the pedal stroke.

“The overall result is smoothing of the torque profile and less fluctuating transfer of power to the back wheel.”

Huron Cycling says that its tests (you can read more about the methods and means of measurement in its white paper) demonstrate that “the Impact drivetrain improves cycling efficiency by more than 4% for a range of power and cadence levels”.

The tests showed that with conventional cranks an average of 197.2 watts was required to hold an average speed of 19.3km/h at a cadence of 71rpm for 30mins on a Tacx Neo trainer set at a 3% slope. The use of an Impact chainset is said to have reduced the power required to an average of 187.8 watts.

“The cyclist can maintain the same speed while exerting less energy or go faster using the same energy,” says Huron Cycling.

This video is intended to show proof of concept; it's not a commercial product. The new patent relates to an Impact chainset with fibre composite leaf springs inside each hollow crankarm.

Huron Cycling says that the improvement in cycling efficiency depends on each rider’s pedalling technique. If a rider maintained the same torque throughout the pedal revolution they’d see no benefit from using the Impact drivetrain, but everyone applies more torque on the downstroke than through the dead zones around the top and bottom of the pedal stroke.

Research published in Medicine & Science in Sports & Exercise supports the notion that the Impact chainset improves effective power during cycling.

Huron Cycling has also developed a power meter incorporated into an Impact chainset. Although this is not covered specifically in the patent mentioned above, earlier US patents 9,403,576 and 9,809,275 described prototype and proof of concept versions of both the chainset and power meter.

Rather than relying on strain gauges, the power meter uses rotary sensors that keep the cost down.

The power measurement is based on the fact, mentioned above, that the crank arms can rotate by several degrees relative to the spindle.

“The rotation angle is proportional to the load applied to the left and right pedals and, therefore, to the torque on the left and right crank arm,” says Huron Cycling.

It says that a rotary sensor system measures this angle with an accuracy better than 0.1 degrees.

Huron Cycling says that its design “can measure left and right torque on Impact [chainsets] at 1500 Hz sampling rate [1500 times per second] with better than about 2% accuracy and low noise”.

“Torque profile, power and much more can be displayed in real-time on GPS cycling computers or smartphones using ANT+ or Bluetooth wireless protocols,” says Huron Cycling.

Will the Impact chainset become commercially available? Huron Cycling says that it partners with bicycle and component manufacturers to bring its technology to market so it’ll depend on whether there’s a take-up from the cycling industry.

"We have had discussions with several bike and component manufacturers so far, one of which has confirmed improvement in efficiency with its internal testing," says Huron Cycling's Willem den Boer.

"Our technology is initially aimed at performance cyclists who care more about details and maximising efficiency than casual cyclists. That would include racing.

If the Impact chainset makes it to production it might well be classed as a technical innovation by the UCI (the UCI says, "A technical innovation is defined as a new system, device or item of equipment that allows an improvement of a rider’s performance, adds new functions to the bicycle, modifies the bicycle’s general appearance or affects any other aspect of the UCI regulations”) and require approval before being used.

"It is too early for UCI approval, but it is interesting to note that conventional [chainsets] also deflect under load," says Willem den Boer. "Our crank arms just deflect 5 to 10 times more and return stored energy in the direction of rotation, so it is a matter of degree of deflection. There is no standard for the amount of acceptable deflection.

"We see this as similar to oval chainrings which, as far as I know, were not a problem for the UCI."

Mat has been in cycling media since 1996, on titles including BikeRadar, Total Bike, Total Mountain Bike, What Mountain Bike and Mountain Biking UK, and he has been editor of 220 Triathlon and Cycling Plus. Mat has been road.cc technical editor for over a decade, testing bikes, fettling the latest kit, and trying out the most up-to-the-minute clothing. He has won his category in Ironman UK 70.3 and finished on the podium in both marathons he has run. Mat is a Cambridge graduate who did a post-grad in magazine journalism, and he is a winner of the Cycling Media Award for Specialist Online Writer. Now over 50, he's riding road and gravel bikes most days for fun and fitness rather than training for competitions.

Latest Comments

- Aluminium can 2 sec ago

While I always have lights on day and night and wear fluro, I have a friend that wears all black all the time and doesn't use lights ever. His...

- eburtthebike 2 hours 4 min ago

A sad case, and one with no winners. The driver can thank her lucky stars that the cyclist wasn't more seriously injured and that the court was...

- AidanR 3 hours 55 sec ago

Bloody hell... How are you doing now?

- ktache 3 hours 9 min ago

And I liked endura too. Got a nice long sleeve mostly merino long sleeve a little while back, in orange.

- matthewn5 3 hours 37 min ago

No, the Ebay lights have been around for several years, this Lezyne light just appeared.

- chrisonabike 3 hours 53 min ago

They shouldn't worry - the second part of the "tariff" refrain is "they can make it in US and they'll do very well".

- Mr Blackbird 4 hours 25 min ago

"At the going down of the sun, it will get in our eyes and cause us to crash into things."

- Rendel Harris 4 hours 33 min ago

Been living in the area thirty years now and Brixton Cycles (and local riders wearing their famed Rastafarian colours jersey) has been an iconic...

- chrisonabike 9 hours 29 min ago

Indeed - but again these are perhaps questions we should keep asking. Even if the immediate answer is "well we are where we are" or "how on earth...

Add new comment

21 comments

As the amount of energy stored in the spring is recovered during the "weaker" part of the stroke, I suspect that there's little, if any, benefit over the the use of oval chainrings. I've used an oval small ring and find it assists particularly in hill climbing. I suspect an oval chainring is the fraction of of the cost of this heavilly engineered crank.

Although my opinion is just guesswork, I would rather see these modified chains and cogs become available, although they would inevitably be very expensive. Sadly, I suppose we'll never see either!

https://road.cc/content/tech-news/new-motion-labs-reinvents-sprocket-increased-efficiency-283111

trade off on these is larger jumps between gears, as sprockets can now only be in even numbers of teeth (or equivalent teeth, as obviously they can have odd numbers of their double spaced teeth.)

Is that an oval axle?

Is it time to do bent cranks again?

I was thinking this too. Time to roll out the old L Crank article again road.cc

Surely, if the spring in in the crank, all that will happen is that when you ease off the torque, the spring will push back, effectively making it harder to push through the dead spot?

Or is the spring movement forward / extension, not rotation?

This. If one side of the spring is acting against a muscle, that is very different to acting against the ground (as in the comparison given of a sprung shoe). Muscles need to work to provide a static force. The ground does not.

It can't be a mechanical effect because a component with moving parts is going to have transmission loss of energy in a way that a rigid component doesn't have. The only way this thing could be beneficial would be if it were more biomechanically efficent, ie allowing the rider to output more watts. There have been many attempts to tinker with chainsets over the years: L-shaped crank arms, Biopace, Powercranks (they were crazy!), O-symmetric as used by Froome and approximately no-one else ever... you can see where I'm going with this. None of them stuck around; this thing won't either.

Is it possible that by smoothing power output from the cranks, it reduces losses elsewhere in the transmission system (e.g. frame, tyres)?

Nope. Can't see that being a real effect at all.

If true, this will only confirm what Jan Heine among others, has been saying for years: a bit of elastic 'give' between pedal and wheel increases performance.

A twisty crankset is not necessary. A frame with the right amount of flex for it's rider provides the same elastic energy storage and release.

The reason given by Jan is very different to that given here by Huron. Jan says the compliance increases the biomechanical efficiency of the downstroke, thus increasing the rider's power output. Huron says it is a mechanical effect and that it decreases the required power. Perhaps both arguments are valid.

https://www.renehersecycles.com/myth-4-stiffer-frames-are-faster/

I'm sceptical of the benefits of bike bits that are more flexible or 'springy' as there's a clear waste of energy going into flexing those parts. However, it is entirely possible for biomechanical systems to become more efficient by storing and releasing otherwise wasted energy (e.g. tendons in your legs whilst running).

Ultimately, I'd want to see some decent testing on this to see if it does provide a benefit or not.

Yes. I suspect that, whatever the mechanism, the elastic properties need to be "tuned" to the rider weight, cadence, power, etc. which would be easier to do with a crank based system than a frame.

Interesting artile isn't it. Not easy to make it work or repeat their findings since rider weight, cadence and strengh all vary and need to be matched to frame spec. And I'm spectical that there's more to it than a simple good match of frame and rider creating something rather unscientific, 'good flow' or something like that. I'm not sceptical that a frame should be matched to the rider. The human body doesn't seem to work best with rigid objects, when cycling our muscles work in a fairly smooth waveform of power rise and fall. If it were a very square wave then a super-stiff carbon bike might be best, ie for a sprinter. But for riding in general and particularly longer distances I'm with him on a certain amount of frame flex reducing stress or 'working with us'. Biomechanical efficiency perhaps.

imo the main reason we get sold ultimate stiffness from bike brands is that of the choice between 'optimised stiffness' and 'ultimate stiffness', only one can be easily mass produced. Plus it sells to our egos.

My own favourite road bikes aren't the stiffest bikes I've ridden at all. I won't win any crits or sprints but I'm not lacking power output in general, still prefer something closer in stiffness to a 90s steel bike than 2015 carbon. I expect carbon bikes will be de-tuned in this area in the comng years (Aether already has been from what I've read?) and one day a big brand will offer stiffness levels as well as frame sizes - for a cost - and we won't hear the end of it from BQ : )

As for this chainset ... nah. Oval rings, yes.

Is this a real saving, or is it related to the ability to measure and calculate power?

does the same riding taking the same bike up the same hill have a lower heart rate?

Can the same rider going up the same hill go faster, when riding flat out?

Yes exactly - I'd like to see real-world usage

I have puzzled this... if wattage requirements are measured at the wheel then sure, those measurements can be trusted. However if measured at the wheel, you would see no difference as maintaining a set speed, with set drag and rolling resistance etc. ultimately requires the same power.

Therefore, we can only assume the power number is taken somewhere on the crank / pedal / BB. In any of these cases, unless the power meter has had its algorythms updated to account for the spring action, any power reading is likely to be inaccurate

Look at the summary of the study linked - it would appear that they measured the subject's 'ventilatory threshold' then tested the cranks with the subject working at various percentages of that threshold. Essentially the implication appears to be (and I'm not an expert on VT AT ALL) that more power was seen at the back wheel (and pedals I assume) for each percentage of VT when the crank was working vs. not. So in essence more power seen at wheel for the same physiological effort.

Obviously it's just one study etc, and people more qualified than me would be able to dissect it in more detail, but it does appear to be at least attempting to measure the right thing.

I could buy the reduction in RPE argument, how much effort is put in to either A) overcoming the dead-weight of your trailing leg, or B) physically pulling that trailing leg through the back portion of the pedal stroke?

Either way, if it is more efficient to create watts on the downstroke and a small portion of those watts are returned elastically to assist in pushing the trailing leg through the upstroke, then maybe the body has to do less work over the whole pedal stroke? After all, I think the 'pedalling circles' argument has been debunked because it is quite biomechanically inefficient to pull your trailing foot back round with your hamstrings?

Pretty much exactly how I imagine those springy shoes work? Bouncing your foot back to the top of your stride?

it's not about downstroke and upstroke as the leg pushing down lifts the opposite leg up. It's about having a smaller reduction in torque applied to the rear wheel when pedals are top and bottom.