- News

- Reviews

- Bikes

- Accessories

- Accessories - misc

- Computer mounts

- Bags

- Bar ends

- Bike bags & cases

- Bottle cages

- Bottles

- Cameras

- Car racks

- Child seats

- Computers

- Glasses

- GPS units

- Helmets

- Lights - front

- Lights - rear

- Lights - sets

- Locks

- Mirrors

- Mudguards

- Racks

- Pumps & CO2 inflators

- Puncture kits

- Reflectives

- Smart watches

- Stands and racks

- Trailers

- Clothing

- Components

- Bar tape & grips

- Bottom brackets

- Brake & gear cables

- Brake & STI levers

- Brake pads & spares

- Brakes

- Cassettes & freewheels

- Chains

- Chainsets & chainrings

- Derailleurs - front

- Derailleurs - rear

- Forks

- Gear levers & shifters

- Groupsets

- Handlebars & extensions

- Headsets

- Hubs

- Inner tubes

- Pedals

- Quick releases & skewers

- Saddles

- Seatposts

- Stems

- Wheels

- Tyres

- Health, fitness and nutrition

- Tools and workshop

- Miscellaneous

- Cross country mountain bikes

- Tubeless valves

- Buyers Guides

- Features

- Forum

- Recommends

- Podcast

feature

Is it always cheaper to do your own bike maintenance? Feb 2025

Is it always cheaper to do your own bike maintenance? Feb 2025Is it always cheaper to do your own bike maintenance? We do the sums to work out when the bike shop is best

If you're a regular rider then you've probably realised that your road bike requires the odd bit of maintenance. There are some bits like changing an inner tube that are pretty simple and cheap to do by yourself, and sometimes necessary if you're on a ride; but what about the bigger jobs, like replacing a bottom bracket or cables? Is it always worth investing in quality tools to do it yourself at home, or is your time and money better spent dropping your bike off with the professionals?

For bike shop staff reading this... don't worry, we're absolutely not suggesting anyone should work on their bike without proper tools or knowledge. And we know how frustrating it can be when a customer brings in a bike and claims not to have fiddled with the limit screws, except there they are, hanging in by a thread.

To save everyone's time and frustration, we wanted to put the theory that working on your bike yourself will save you money - particularly in the long run. So, we've got some pretty standard bike maintenance scenarios and put them to a local bike shop, The Bike Mill, based in Queensbury, West Yorkshire to price up. We've been told that Ralph the shop dog accepts tips in the form of dog biscuits, so make sure you add that to your tally.

Alongside this, we've calculated roughly how much doing the same bit of maintenance would cost if you did it at home.

Let's dive in...

Replacing or repairing an inner tube

Replacing your inner tubes (if you run them, of course) is one of the first things you learn when you're figuring out how to maintain your bike. Unfortunately, punctures are more of an inevitability than an 'if' if you ride in the UK so it's important you know how to fix one in case you're not in a shop when your tyre goes flat.

How to patch repair a bike inner tube

How much it costs at home: If you were to do this at home, you'd need a pump, a replacement tube if you're replacing it, or a patch kit if you're wanting to repair it. And then some tyre levers if you have a really stubborn tyre.

If we say a replacement tube costs around £5 (depending on brand, width and valve length required), a hand pump costs around £20, a patch kit is usually a couple of quid, and tyre levers you can also pick up for around £5. The total if you're replacing/repairing the tube at home (and need to buy the equipment to do so), is around £25-30. If you already have the kit? Then around £5 just for the tube.

How much it costs at a shop: Around £10 to get someone to replace the inner tube for you and pump your tyre back up.

Changing a bottom bracket

Bottom brackets - get the insider info on your bike's beefiest bearing

Now this one is a bit more time consuming and requires more tools than changing an inner tube, but is still handy to know how to do. If you start to feel your bottom bracket grinding a little when you're riding, (especially if you've been riding your bike through a British winter), it could be time for a new one.

First up, you need to find out what type of bottom bracket you have. The two main types are press fit and threaded. Both require specific tools to remove and replace, and within each type there are several more subsets of standards just to keep you on your toes. So unless you have the same BB across all your bikes, you may need more than one tool to replace each one.

How much it costs at home: For the sake of this extremely scientific article, we'll assume the threaded BB is a BSA or English threaded bottom bracket. So, what do you need to remove/replace one? Firstly, a compatible bottom bracket tool. Like most things, you can spend a lot or a little, so we'll go somewhere in the middle and say roughly £15 will get you a threaded BB tool.

Then, you'll need your bottom bracket, which again, depends on the make and model of your BB, but roughly around £20 should see you get a semi-decent one. If you want a bit of bling from the likes of Hope or Chris King, expect to spend much, much more.

You may also want a torque wrench that tightens up to 40Nm, which may set you back around £40+ for a set. So, for a threaded BB removal/replacement, you're looking at around £75+ for the tools and bottom bracket.

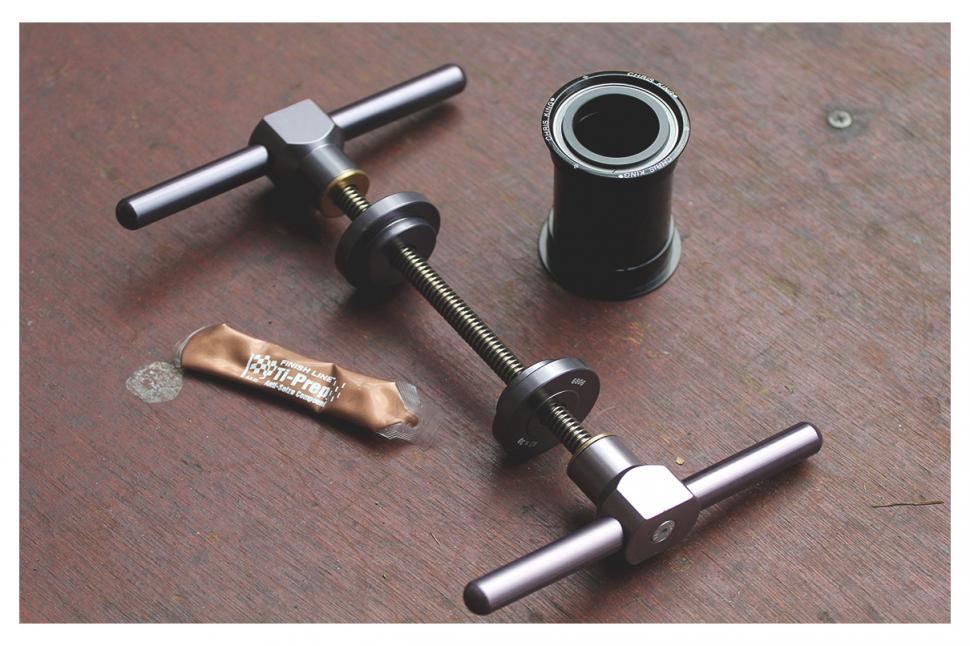

When it comes to a press fit BB, you need a bit more specialist kit, including tools to remove the crankset (perhaps an Allen key), a bottom bracket removal tool, mallet and a bearing press. We're going to assume you have the Allen keys lying around, but if not you can pick up a decent set for around £15-20.

The bearing press is probably one of the most expensive tools you can buy for a bike maintenance, with ones like the Park Tool HHP3 retailing at £100. You can get cheaper options, of course, for around £50. A press fit BB removal tool will set you back around £25, and a soft mallet won't cost much - you can even use the one you bought for camping many years ago. A replacement BB will set you back between £15 and £100+ depending on the brand/type.

In total, that's around £95 at the cheapest, depending on tools bought and BB type.

How much it costs at a shop: For a press fit BB, The Bike Mill quoted us £45, and for a threaded basic BB, £40. And, something we think is important to highlight if you have a press fit BB - if you take it to a shop, you don't have to psych yourself up to hit your lovely frame with a mallet.

Replacing gear cables

Over the last decade or so we've seen the majority of bike brands shift to internal cables and reduce as many of the outers on show as possible. This has led to some pretty radical bar, stem and headset designs, which we know cause a few grumbles from those who work on them regularly. But how much does it cost to actually replace your bike's cables?

How to replace gear cables on your road bike: 2 top tech tweaks for smoother shifting

How much it costs at home: Cable sets from a reputable brand like Shimano or Jagwire cost around £20 for both inners and outers and usually include all necessary fittings. Tool-wise, you'll need cable cutters (usually around £25, like these from Topeak), Allen keys (roughly £15-20), a pick (don't need to be road bike specific and can be picked up from a hardware shop or Amazon for around £5-10 a set).

This brings the total to around £65+.

How much it costs at a shop: Going off the basis the cables are for a 2x mechanical groupset setup, around £50.

Replacing your bar tape

Ahh, the old bar tape conundrum. Do you wrap from the inside out or outside in? Match on both sides or go opposite? It's an argument that still remains rife within workshops and social media today, but the main takeaway is that it looks neat and it's functional. But is it worth doing yourself?

How much it costs at home: Thankfully you don't need many tools for this job. Just something to prize the bar end caps off (usually a flat head screwdriver or an Allen key) and then the bar tape (usually between £10-40) and some scissors and electrical tape for a really neat finishing job.

Wrapping your own bar tape can be incredibly frustrating if you're not well-versed in it, or it can take literally minutes to do if you are. If you fall into the former category, it might be worth your time just asking the local shop to do it for you.

How much it costs at a shop: If the customer supplies the bar tape, then £15 for labour. If not, expect to spend between £15-40 depending on the bar tape.

Bleeding your disc brakes

If you've noticed your brakes becoming spongy and you've still got plenty of life left in your pads then it could be time to give them a bleed. Bleeding your brakes can be a messy affair if you're not 100% sure on how to do it, and personally, after an incident involving DOT fluid and some cream carpet, I'd rather let the professionals handle it.

But, if you're keen to try it yourself, could it be cheaper?

How much it costs at home: Depending on the brand of brakes you use (SRAM or Shimano, for example), the price of equipment needed to bleed your brakes may vary. That being said, you can buy brake bleeding kits for both SRAM and Shimano, with 'official' ones costing around £50. If you go off-brand, however, they can be cheaper.

The kits often contain syringes, master cylinder funnels, and caliper bleed spacers. You'll also want some nitrile gloves which you can buy a multipack for a couple of quid at the local hardware shop, and the brake fluid (mineral oil or DOT) which costs around £10.

You'll also need a Torx bit and/or Allen keys (which one depends on your brake calipers) and some pliers would be helpful when removing the brake pads so you don't contaminate the surface. The cost of these is around £15-20 for a set of good Allen/Torx bits, and around £10 for pliers.

Disc brake refresh: maintenance and top tech tweaks for effective and quiet braking

So in total? Roughly £80. Of course, you can re-use these things again and again, so if you do it annually, it'll pay for itself in about two years.

How much it costs at a shop: The Bike Mill quoted us £20 per brake, or £40 for both front and rear brakes to be bled.

Conclusion: bike shop or DIY?

It goes without saying that every job is different, and everyone's knowledge of bike mechanics and ability to dedicate time to fixing their bike is different. And we would never suggest doing your own maintenance if you're not confident about what you're doing - the most important thing is that you keep your bike in a safe enough condition to ride, and sometimes that means dropping it off at the bike shop so they can take care of it.

It might be surprising to some to find that the bike shop is often cheaper than doing it yourself, usually because the investment in some tools can be pretty significant. That being said, if you develop the knowledge and acquire the tools to use again, they will pay for themselves over time.

But, neither doing it at home or letting the professionals work on it is right or wrong. Everyone's circumstances are different, and if you don't feel confident working on your bike, then there is no shame in dropping it off at a shop.

Equally, we wouldn't recommend making the bike shop's job harder by having a go at something and then creating more problems than you started with. If you don't know how to bleed brakes and aren't comfortable following YouTube or reading an article, it's not worth the hassle of potentially getting mineral oil all over the carpet and/or stopping your brakes from working entirely.

What jobs do you do at home, and what would you leave to the professionals? Let us know in the comments.

Rebecca has been writing about bikes for four years, after a typically ill-timed career change pre-pandemic. She's been riding bikes since she can remember, and fell back in love with them after realising it was faster, cheaper, and more fun than getting the bus to work. Nowadays she enjoys all kinds of bikes, from road to eMTB and is training her border collie pup to become a trail dog.

Latest Comments

- OnYerBike 7 min 27 sec ago

There's a recent video on Pog's instagram showing him training on a TT bike but in a normal road helmet: https://www.instagram.com/reel/DExEGUTMGA2...

- mdavidford 20 min 9 sec ago

Which analogy? I see a couple of metaphors there ('megaphone' - doesn't seem to be much preposterous about that; 'angry grandpa' - I don't think...

- nodgedave 26 min 10 sec ago

#norfolkcountycouncil ... read and learn.

- nodgedave 28 min 7 sec ago

Are they like ... well hooks hanging on the ceiling you hang a bike wheel from like my shed for 20 years? No mention of the oil or water dripping...

- bikeman01 34 min 35 sec ago

Its frankly unbelievable that the police would throw so much resourse at this by trawling social media to find supporting evidence of your swearing...

- Bungle_52 1 hour 10 min ago

This is the reply I got when I reported a van completely blocking a cycle path....

- chrisonabike 1 hour 43 min ago

But presumably they a) did something (and can proudly say so) and b) successfully used up an active travel budget / got a funding tranche......

- bobbinogs 1 hour 44 min ago

I don't know TBH, but I would investigate by firstly identifying the cable. If it is the rear gear and looks/acts like an inline adjuster, drop...

- chrisonabike 3 hours 26 min ago

Otherwise law-abiding...

Add new comment

52 comments

I have gradually done more and more jobs myself mainly because there was a long wait to get into the LBS and also some of the jobs I could have done better myself - have picked up after services to find gears jumping, loose cassettee. You are lucky if you have a good, reliable one .... I have mastered tubeless tyres now and Di2 is straightforward as are headsets, disk brakes, BBs (not PF) the only thing I can't seem to get my head around is cables (brakes and gears) on my commuter bike so leave that to the pros.

I run maintenance sessions to support people doing maintenance on their own bikes and 1:1 for people who want to go full strip down. I don't cover bleeding brakes, extended wheel repairs etc

I will balance, I still essentially book time out for my own bikes, my down time is for riding not fixing bikes.

I'll balance all of this though, you're paying for the experience, knowledge, tooling and piece of mind that should you have an issue the workshop will handle it. It's all good until the BB is seized, bearing race stuck, Pad retaining pin rounded. I get lots of failed bleeds through, lots of poorly setup mechs from keen enthusiasts etc

Greater integration means jobs can take longer, some cable routing can be sub 15 minutes or over an hour.

Power to you if you're capable with the tools, otherwise support your local workshop.

The problem with that is that, to get to the point of being capable with the tools, pretty much everyone has to first go through the stage of being somewhat ham-fisted with them.

I my be one off, but I enjoy working on my bikes! But for those rare jobs that take an expensive tools (and some expetise) that will sit, ... and sit, .... and sit. I leave to my LBS. For them it's just the cost of doing business AND they will perform these jobs on a regular basis. I do splurge on quality tools that I will use regularly ("cheap" tools are an absolute waste of money!).

I enjoy working on my bikes as well to the extent that I assembled them from the frameset, built wheels etc. This said my bikes are of a past age (low-tech) and possibly much more straightforward to work on. This does mean that I get the bike I want (gearing, etc) and know how to fix it when things go wrong. I do use a local bike mechanic for things like facing where I don't have the tools.

I've tried building wheels and I could do it adequately, but to really do it well, is an art I leave to others, but I will re-true when needed. My bike too, is "low-tech", I still have rim brakes.

i will happily pay for someone else to endure the faff of restoring wheel concentricity, trueness and dishing..

"Equally, we wouldn't recommend making the bike shop's job harder by having a go at something and then creating more problems than you started with."

But that would take away a general source of amusement at my LBS.

When I have mucked it up (rare, but I do!), I upfront admit it. They know me at the LBS and will work with me.

Oh yeah, me too. I'm in the particularly fortunate position that my LBS (which isn't actually my most local one these days) is owned by a friend of mine.

You can get a lot of specialist tools massively cheaper on AliExpress, and if that makes you queasy then Amazon often has the same things marked up a little more. I've got loads; a particular highlight being the bearing press kit for £25 that is totally comprehensive (or the disc brake bleed kit that I use really frequently).

Generally I prefer to do what I can myself because it's a faff booking a slot for work at a bike shop, taking it there, being without that bike for a little while etc. I get that some jobs make people nervous doing themselves, but there are so many good Youtube videos talking you through things step by step these days, very much lowers the bar for required knowledge.

Absolutely agree about AliExpress - although a very few frequently used tools I've replaced with Park Tools, but only when they've worn out or been lost in the man-cave or been "borrowed" by one of the younger cyclists in the family.

All the knowledge beyond "Richard's Bicycle Book" ** in the 1980s I've toppedup with YouTube

** not everyone will remember that far back

And you can even buy them more than once!

For that reason, and others, unless you only plan to cycle for a short period of time, buying quality tools is worthwhile -- for the most part. There are a few tools that are sufficiently exorbitantly priced that I've just manufactured my own version, but that's a rare situation.

Admittedly, I own tens of thousands of dollars of tools -- only some are bicycle-specific -- but if you use a tool a few times, the difference between having spent 10 or 50 on it stops mattering, and you're more likely to be happy with the latter as the number of uses increases.

"Buy once, cry once".

Also, one needs to be extremely careful with Chinese tools. For example, someone applied a Chinese measuring tape to my cabinet saw, before I obtained it. I later measured the measuring tape, after finding the saw inconsistent, only to realize that the tape was both long and short, by several mm, depending on the location. Apparently it was a hand-painted, artisan measuring tape, but I didn't appreciate those qualities in this instance.

Jeez not the "its Chinese its rubbish" angle....

Bearing in mind this entire article is "is it worth buying the tools to do a job yourself" I am pointing out that these days you can get fairly decent tools that are easily good enough for occasional home mechanic usage for way cheaper than the prices quoted.

I would suggest those "few tools that are sufficiently exorbitantly priced that you've manufactured your own" are exactly the sort of things AliEx does so well. I would buy a top quality torque wrench because I use it all the time and the quality of the tool really matters. I would buy a steerer cutting guide from AliEx because its something I don't use that often and its way better than the old stem I always used instead. I'd also buy tools like internal cable routing guide that you can perfectly well live without, but life is easier when you have one (and you wouldn't buy unless it was a fiver). There are also tools that you can only get on AliExpress because the only brands that make them only sell them there, like lazer steerer alignment gauges and the tool to convert your mech alignment gauge to align your shifters.

If you think it is all cheap Temu tat, you are very much mistaken.

I have bought Chinese made tools and suffice to say, they were universally poor quality and ended up in the scrap bin; all my tools are now Taiwanese made and I would recommend these for their quality of design and material.

Which is very much what I did not say. I did not say that everything from China is rubbish. I did say that one has to be very careful buying tools from that country -- which places very little value on quality and has zero respect for intellectual property. Do I own some Chinese-made tools? Yes -- although almost-exclusively ones that need very little precision, or have no moving parts at all, or can present no danger to the user upon failure.

I also referred to the fact that many people who save two-thirds by buying cheap Chinese tools wind up buying three of them before a better tool would've even been broken-in.

Much of that is debateable, but the counterpoint is that a home mechanic will never wear out or break a quality tool. So if one has decades of cycling ahead of them, the added expense of that quality tool is quite likely zero or less, over its lifespan, versus buying N cheaper versions. N+1 is cool for bikes, but not so much when replacing broken or worn-out tools.

Stripping one fastener with a poor-quality tool and spending a day trying to remove the subsequent lump of metal overwhelms the proposed cost-savings of most such cheap tools.

You may not get what you pay for, but you always pay for what you get.

I have recently obtained a SPD axle removal tool from eBay, ali, anodised in blue, wanted orange. I presume it's Chinese made, too much of a bargain to have been made anywhere else. Far better than the Shimano plastic version.

Now my Japanese JIS2 driver is incredible, and I have only just found it's perfect on my Crane Rittan brass bell, also Japanese. Odd that...

If we're getting down to the cost of a set oftyre levers, you'd have to factor in the time and trouble of in my case two 12 mile round trips to an LBS (less of the L, I'm afraid).

I can do most jobs. I leave bigger jobs like messing with the headset/wheel servicing/truing and messing with the bottom bracket for the LBS to deal with. mainly because I dont have the tools or the required skill to do it. Although servicing wheel hubs is probably very simple these days as all you need to do is pop the old one out and put a new one in or clean and repack the old one with fresh grease if its still in good condition.

As per the Clint Eastwood line, 'a man's got to know his limitations'..

Cartridge bearings generally require a bearing press kit to fit them, as it's supposed to be a tight fit to prevent unnecessary play. I bought one as my Hunt rear wheel had excessive play, only to find it was the nut adjacent to it that was loose, so my very shiny, new kit is sitting gathering dust in a corner of the bike room!

Pages