- News

- Reviews

- Bikes

- Accessories

- Accessories - misc

- Computer mounts

- Bags

- Bar ends

- Bike bags & cases

- Bottle cages

- Bottles

- Cameras

- Car racks

- Child seats

- Computers

- Glasses

- GPS units

- Helmets

- Lights - front

- Lights - rear

- Lights - sets

- Locks

- Mirrors

- Mudguards

- Racks

- Pumps & CO2 inflators

- Puncture kits

- Reflectives

- Smart watches

- Stands and racks

- Trailers

- Clothing

- Components

- Bar tape & grips

- Bottom brackets

- Brake & gear cables

- Brake & STI levers

- Brake pads & spares

- Brakes

- Cassettes & freewheels

- Chains

- Chainsets & chainrings

- Derailleurs - front

- Derailleurs - rear

- Forks

- Gear levers & shifters

- Groupsets

- Handlebars & extensions

- Headsets

- Hubs

- Inner tubes

- Pedals

- Quick releases & skewers

- Saddles

- Seatposts

- Stems

- Wheels

- Tyres

- Health, fitness and nutrition

- Tools and workshop

- Miscellaneous

- Buyers Guides

- Features

- Forum

- Recommends

- Podcast

Investigating Shimano’s snapping cranksets Sept 2023

Investigating Shimano’s snapping cranksets Sept 2023"Banned" bike shop claims Shimano won't let it inspect Hollowtech cranksets as part of "inspection and replacement" programme due to failing 100% of them

One year on from Shimano announcing a voluntary inspection and replacement recall of Hollowtech cranks, a UK-based bike shop has claimed it has been "banned" from the inspection programme after the components giant's main UK distributor took issue with its policy of sending all cranks back to the manufacturer due to safety concerns.

Few were surprised when Shimano finally acknowledged the issue last September, cyclists having reported cracks and delamination on 11-speed road cranksets for years. However, in Europe and the UK, to the frustration of many, including one lawyer from Leigh Day that we spoke to, Shimano opted for issuing an "inspection and replacement program" rather than a full product recall.

This meant bike shops were tasked with inspecting customers' cranks, documenting any issues and, if found, sending concerning cranksets back to Shimano for replacement. There have been numerous issues with this process cited in the past 12 months, from legal fears over liability in case of incidents, through to questioning whether Shimano should instead be recalling all relevant cranksets regardless of present damage.

Now, however, another talking point has been raised as Mapdec Cycle Works, a Lake District-based bike shop that also uploads to its YouTube channel, has claimed it was "banned" from the inspection programme after revealing it is sending all cranks back to Shimano.

The shop's owner and founder Paul Vousden posted a video last week in which he suggested that for all Shimano cranks included in the recall which are brought in by customers, "We don't bother inspecting them, we just ship them back, it seems to be the industry norm on all the bike and mechanic forums that we follow, they all just say just ship them back, get a new set."

This seemingly did not go down well, Shimano's UK distributor Madison contacting the bike shop to say they are now on a 'banned list' and will not be paid the £35 that shops are given for each crank inspection.

"Shimano took a little bit of offence to that," Vousden said in a subsequent video uploaded to YouTube. "We got a phone call from Madison who had apparently spoken to Shimano and they asked us to take the video down, which we haven't done, and they said that we are adding you to the banned list, which means that we can no longer administer their crank inspection and replacement programme."

The Mapdec owner also clarified that, despite his comments in the previous video, the shop was inspecting cranks as per Shimano's requirements, and confirmed his business will still be supplied with Shimano stock, the 'ban' relating to them not being able to receive the £35 reimbursement for crank inspections that the components giant is offering to bike shops.

"The interesting thing for me was there is a list of banned shops, I didn't realise that," Vousden said. "The guy was like 'we are adding you to the list of banned shops'... how many people are on this list? The reason I'm concerned about that is that they are judging shops on their pass and fail rate. Because we had a one hundred per cent fail rate we've been banned."

Vousden told us he had not been given the names of any other 'banned' bike shops, while Shimano and Madison also opted against commenting when approached ahead of this story's publication.

Mapdec's owner continued: "We do inspect them, even though I said we don't inspect them. We do, we have to because in order to send them away to Shimano we have to take them apart, we have to clean them, we have to fill in this form, and on this form we have to take pictures at the back, the side, the front etc and show that we have actually cleaned it and done the inspection.

"But, it asks us, inspection passed or failed? There's no in between. It's a pass or a fail, so our policy has always been if it's clearly failed, it's obvious, it's a fail. But we would never write the word 'pass', we would always write something like 'customer reports creaking, customer not happy with the pass, unsure, please check'. So we thought that we'd send them off to Shimano and Shimano would then offer a second opinion.

"They didn't do that apparently, according to the guy at Shimano. We were just shipping them, we naturally thought that surely if we put some comment they have got to do some extra checks that we're not capable of doing or they have some more insights and processes, but the process clearly has been they've just been sending them [replacements] out.

"Shimano never ever sent one of these [inspected customers' cranks] back to us [...] it never happened, they always sent out a replacement, so that's what we did, that was our policy. I've always always put our customers first and I've never thought I'm going to be on the side of Shimano here."

As per the 36-page dealer's manual for the crankset inspection method, mechanics are required to undertake a process of inspecting and cleaning. The recall of last September is for 11-speed Hollowtech II road cranksets that were produced between 1 June 2012 and 30 June 2019, and covers the model numbers: Ultegra FC-6800 and FC-R8000, and Dura-Ace FC-9000, FC-R9100, and FC-R9100-P.

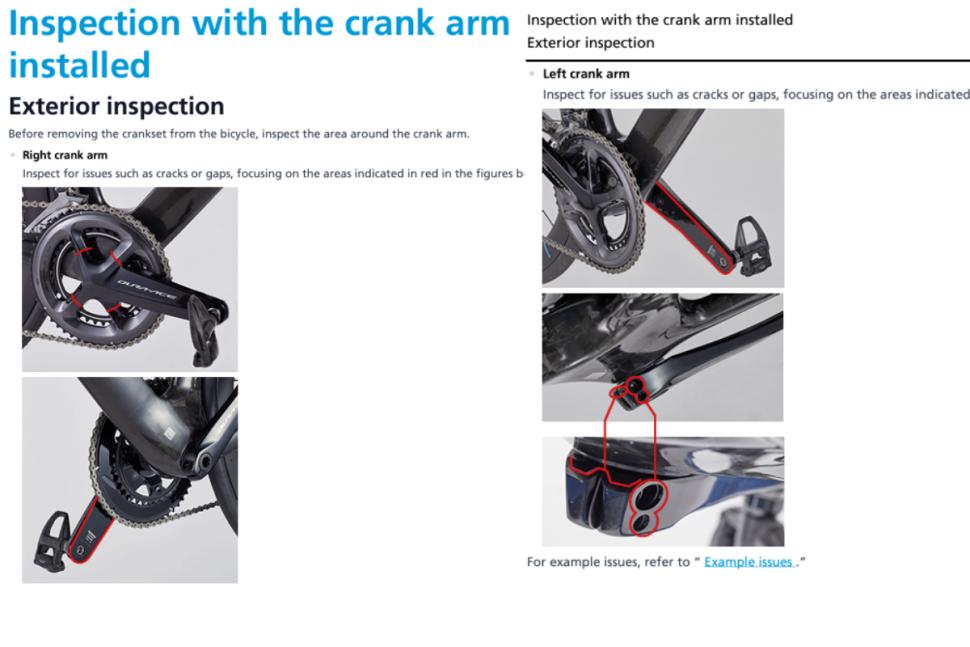

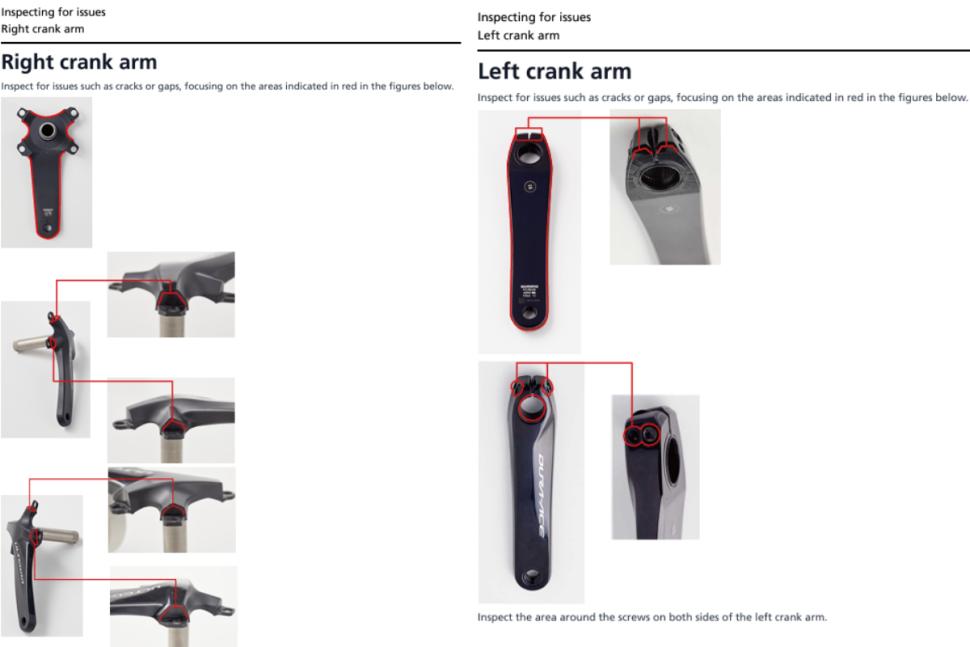

Once a relevant crankset has been identified, bike shops are asked to complete an inspection with the crank arm installed, looking for "cracks or gaps" in the indicated area or listening out for "abnormal noise".

With the crankset and chainrings now removed from the bike, mechanics are asked to clean it by following multiple pages of instructions included in the manual.

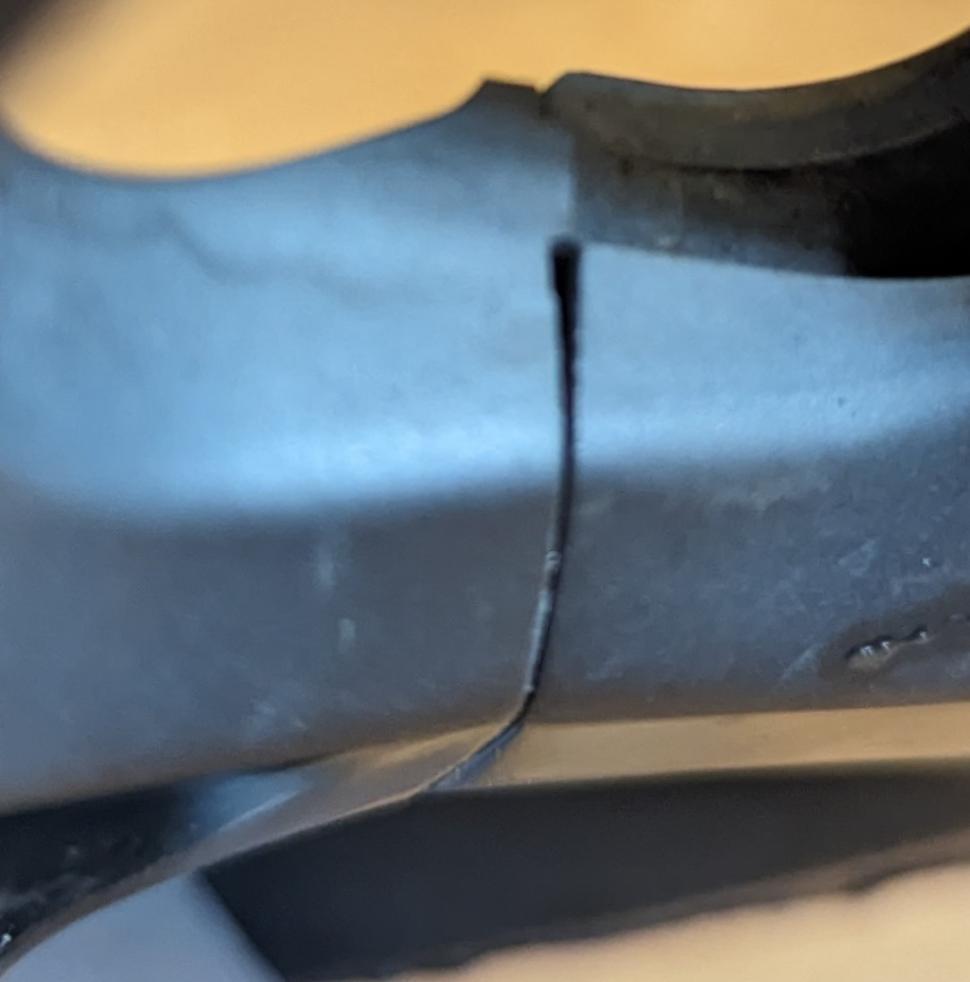

Then, an inspection of the removed crankset is required, again, bike shops told to look for "issues such as cracks or gaps in the crank arm" and areas indicated in the manual. If found, "immediately stop use and replace the target product", it concludes, suggesting that if no issues are found the chainrings and crankset can be reinstalled and continue to be used.

One concern that has been raised by the inspection process is the fear of riders whose cranks may appear fine at the time of inspection, but eventually fail. This is a topic that has been widely discussed online, one forum post on the topic asking: "As a local bike shop, is there any benefit in 'passing' a Shimano crank that's being inspected under recall?

"We're not material experts and even if we're sure it's okay it could fail in a short space of time. I doubt there would be any liability on the shop, but there could still be reputational impacts with some customers (you said it was fine but it still broke). Surely it's better just to send it back, the customer gets a new part with fitting and the shop doesn't have any negatives? Worst case Shimano examine it and send it back, in that case you have followed their guidance and if it fails then the emphasis is all on Shimano and their checker."

Likewise, in Mapdec's video, the second speaker explains that exact scenario happened to him, his crankset passed at the beginning of the recall only to fail during an effort not long after.

"We see comments now on our videos on this point, basically saying: 'Okay, you've checked it, what's to say it's not going to fail tomorrow or next week? What gives me the confidence to keep riding knowing that this will hold up and not fail on?'," they asked.

Madison did not comment on why Mapdec will no longer be paid for inspections, but the bike shop's video suggests it believes it was its 100 per cent fail rate that caused it.

A quick look on online forums suggests the fail rate experienced in inspections at other bike shops varies, especially between climates. Hotter, drier locations seemingly fail fewer cranks than wetter locations like the UK.

Echoing Mapdec's stance, one comment on a relevant thread says: "My shop wants no liability for this, so customers can send it in when they want, but we are warning all of them that unless Shimano says they are safe, they are unsafe. We've sent 12 cranks in, saying all have failed. All 12 have been replaced."

Incidentally, Mapdec says it will continue to inspect and document crank inspections if requested by customers, doing the work and completing the form, but will ask riders to take it to another shop to send back to Shimano.

"Our policy was always we don't want to be the one that says this is a pass, we always thought that, even though Shimano gave a liability release, that liability release in our mind wasn't strong enough," Vousden said. "Also we had customers coming up to us and saying: 'Well how do I know it's safe?' They'd come back the week later and say: 'Can you inspect it again it's still creaking? I'm not convinced this is not going to fail... I want a new one, I'm just going to keep coming back every week until you fail it'.

"The way I've played through it in my mind is let's say you weren't a director of the business and you had a nasty accident and broke your pelvis or something like that and you couldn't work, you would call a solicitor and try to seek compensation. I think that solicitor would very quickly identify there are two places to source compensation, from Mapdec — we inspected it, we said it was safe and we would be the last person to have touched — and Shimano.

"That claim would come into me, I would say: 'Hey, I've got a liability release from Shimano, this is part of a crank recall'. But even if that played out, it is still a load of time and effort and stress and I've got better things to do than fight out a case... we're busy enough as it is, I don't need to be in communication with insurance companies and solicitors and doing this, even if it turned out I could just shift everything to Shimano.

"I'm really proud of our stance, I will always put my customers first and I always think so long as I have customers I'll have suppliers. We've not been banned from supplying Shimano, they were absolutely clear on that. We can still do inspections, we are just not going to be paid for it."

On the legal concerns, last year we spoke to Leigh Day partner Thomas Jervis in an episode of the road.cc podcast, the solicitor telling us the whole recall is "a mess".

"I personally don't understand why it's still acceptable in the eyes of Shimano for consumers to be using this component as part of their bike until it basically fails," he said. "It's lose-lose for cyclists. Shimano can't have it both ways.

"The number one priority for Shimano should be that no more riders are harmed. I think the focus should be on preventing these accidents happening before they do, I see too many of them in my job."

Do you work at a bike shop inspecting Shimano cranks as part of the recall? We'd love to hear your thoughts in the comments, or email us at info [at] road.cc

Dan is the road.cc news editor and joined in 2020 having previously written about nearly every other sport under the sun for the Express, and the weird and wonderful world of non-league football for The Non-League Paper. Dan has been at road.cc for four years and mainly writes news and tech articles as well as the occasional feature. He has hopefully kept you entertained on the live blog too.

Never fast enough to take things on the bike too seriously, when he's not working you'll find him exploring the south of England by two wheels at a leisurely weekend pace, or enjoying his favourite Scottish roads when visiting family. Sometimes he'll even load up the bags and ride up the whole way, he's a bit strange like that.

Latest Comments

- DeelitedManchester 11 min 38 sec ago

I can't resist asking this:...

- wtjs 15 min 26 sec ago

The driver claims he "accidentally stepped on the gas too hard"...

- OnYerBike 1 hour 17 min ago

Unfortunately I can't recommend the Magicshine Seemee DV - I have one and am currently in the process of trying to have it returned and refunded as...

- slc 3 hours 30 min ago

TBH the west (Barton Hill) part of the scheme looks like a much larger change than the east (Beaufort Rd) part. Some drivers living in the west...

- Rendel Harris 3 hours 6 min ago

If you bothered looking at the link you would see that it is not one of their reflective jackets, it is fluorescent with only a small number of...

- Owd Big 'Ead 10 hours 15 min ago

You need to get out of Derby then. Go somewhere else, because while not perfect, Derby is streets ahead of the vast majority of places I've lived...

- HoarseMann 12 hours 30 min ago

Driver injured after car flips onto its roof https://www.bbc.co.uk/news/articles/cy0g9rpp8x9o

- mark1a 12 hours 48 min ago

I don't think he wants to talk about it...

- Rendel Harris 13 hours 17 min ago

Ach, dinnae fret...

Add new comment

91 comments

No it dosnt ,you get shipping labels from Madison to send them back .You get paid to follow their protocol to check them ,they admitted to not doing that yet taking the payments .They could have refused to be part of it .

They're being paid to do work on behalf of Shimano effectively. If they're not doing this in a way Shimano approves of, then fair enough - they don't do the work, they don't get paid. That's fine.

But they should still be able to send any unreliable cranks to Shimano!!! Shimano should not be then refusing to take the cranks!

The root issue here is that Shimano - having already spent a decade denying there was an issue - is trying to avoid fully recalling these unsafe cranks. The root cause is that Shimano is trying to duck their responsibility for their own poor engineering and manufacturing. The root cause is Shimano insisting that LBSes take on a task that LBSes are *not* qualified to do - along with the liability arising from that inspection that some legal systems may not allow the inspecting party to get out of, regardless of what Shimano stick on a bit of paper.

The issue here is Shimano. They've behaved unreasonably in denying the issue. They're now behaving unreasonably in essentially refusing to do their own work, and refusing to take responsibility.

I hope they get hammered in law suits on this.

The root problem here is Paul literally admitted not following protocol .Him being banned is his fault and to go on you tube and whine about it is typical of the era were In.His statement saying his way is " industry norm " is also nonsense .Him.and a few shops he knows dosnt make it " industry norm " I'm in the trade and I don't know ow a single shop that does it his way.This is all on him noone else .A social media following dosnt give him right to claim money for not doing a job he agreed to do .

No, that can not be the root problem. There would be no such protocol if not for Shimano:

1. Making faulty cranks.

2. Worst of all, fobbing everyone off for over a decade.

Whether the shop did the work or not is another question, but it's not the root cause. The shop says they did the work required, but then always sent to Shimano for inspection regardless. Shimano say they didn't do the work (I guess) and have removed them from the programme.

However, this shop can not even _send faulty cranks to Shimano_ anymore.

That aside, the whole protocol is ridiculous. And the shop's behaviour is entirely reasonable, given the stupidity, unreasonableness, and shiftiness of Shimano's protocol. That is the root cause.

Seems to me like Shimano's protocol is just a way of trying to dodge replacing all of the faulty cranks. It's obviously a problem with their manufacturing method of glueing the cranks together and they must have made changes to their manufacturing as they don't include newer cranks in their program. So, they're just trying to dodge round their own mistakes, when they should just replace all of the dodgy batches and not keep dicking around and causing their customers to have crashes.

He made a video crying about being banned by Shimano after saying himself he didn't follow the protocol he agreed to by doing the work .

Shops were asked to make the inspection and mark them 2 ways, pass or fail ..

He admitted to not doing that and sending back 100% of cranks .He also suggested his way was " industry norm "

His claim he got all the cranks ge sent replaced is beyond stupid .

Shimano paid him to decide ,if he sent them back they were supposed to be failed .He expected Madison to do an inspection that he has already been paid for .

You don't get to sign up to it then make up your own rules. You just say no thanks and move on send customers to another shop .Shimanos failing cranks arnt the issue here ,this is their own doing .The way he's not saying no we do inspect them is just digging a bigger hole .

Pretty sure there's no crying in that video. They both generally look quite smiley and cheerful to me.

Laughing on the outside...

Problem is Shimano will have deeper pockets than most LBS' so they will win.

Mapdec appears to have followed Shimano's protocols because otherwise they couldn't submit the photographs of the cleaned parts as required. My interpretation is that Mapdec is just not comfortable saying that this constitutes an inspection that could serve as a basis for certifying a part as defect-free, and I don't blame them. I would expect ultrasonic testing or at least dye penetrant for surface crack detection, and pass/fail criteria to be defined by Shimano's engineering team. The inspectors should also be certified in order to assure Shimano that they are qialified to perform the inspections to their requirements.

I'm not sure that they could simply refuse to do the work. If they are a Shimano retailer, they really need to accept returns of potentially faulty Shimano goods. I'm not familiar with British consumer protection law but in Australia, the retailer has an obligation to accept return of goods that are not fit for purpose.

He literally said it on video and has now changed his mind .He also said it was " industry norm " to send all back .That's a lie ,him and a couple of shops he knows isn't industry norm

Of course they can. They are literally being paid to do the work. They quit the scheme and stop doing the work.

The only things they then become liable for are cranks they have directly sold. Even then - they pass that back to the suppliers - either the Bike Co's or Madison as Shimano's UK agents.

The problem comes when they want to have their cake (the payment) and eat it too (always send cranks back).

I don't disagree with you on what may /should be an inspection .

They agreed to be part of it then made up their own rules claiming its " industry norm " to then say when called out oh no we do inspect them .

It's a bad look for a shop like them who are so meticulous .At the least if they had issue with it they should have taken advice from shimano if what they were asking didn't seem right .They didn't, and it seems to me the You Tube stuff as usual he got a bit carried away by saying we just send them back .

We all agree shimano have handled this poorly in the EU ,but I can see exactly why they would do it .Going on You Tube to complain would get more publicity and it's worked a charm

Really have no sympathy for them .He has taken money to do a job ,he could have refused to be part of it .He didn't follow the protocol so was banned .To go on you tube and cry about it now is pretty pathetic. For a shop so meticulous in what they do by their you tube videos this seems odd at best to make up your own rules .For them to suggest it's " industry standard " to return all cranks is utter nonsense .I'm in the trade and don't know any shop that does what he claims is standard .That's a lie .

If they were being paid £35 for inspecting the cranks, but they didn't inspect them, surely they haven't been fulfilling their contract?

Madpec say, 'We don't bother inspecting them, we just ship them back...' Then go onto say, 'We do inspect them, even though I said we don't inspect them.' So Madpec have, by their own admission, been caught miss speaking. Shimano may think that a straight forward lie has taken place ; I don't know the answer to that . I would say that at the heart of many contracts is mutual trust and respect. If you lie you have broken that contract and can no longer be trusted. So it's no surprise that having stated, 'We don't bother inspecting them..', that Shimano has, having taken Madpec word for it, given them the boot.

Shimano doesn't smell of roses though a straight forward replacement a few years ago might have done something but it's way too late now. Other manufacturers exist.

Shimano are ruining their reputation. As if their initial reaction to these faulty cranks wasn't bad enough - denying the issue for a long while and taking ages to finally acknowledge and do something. Now they're persisting with this utterly bonkers semi-recall scheme, where they're expecting small, independent bike-shops to become experts at identifying potentially hidden epoxy failures; and expecting customers to be happy to continue using these potentially unsafe crank-sets, and excluded from the recall programme cause their (non-expert) LBS "passed" their creaking crank, cause the LBS is afraid of pissing off Shimano and has to "pass" at least /some/ cranks.

Just keep using that crank, and just hope it doesn't one day have a sudden failure that might lead to you face-planting in style. Genius response Shimano! Great customer care there! What on earth are Shimano doing?

I will never ever buy a Shimano crank-set, or a bike with a Shimano crankset. Always been a bit suspicious of these glued-together cranks, always had a niggly feeling that HollowTech was a bit of a sketchy idea (and ugly). Shimano's reaction on this absolutely cements it for me that I'm never going near their hollow, glued cranks.

Terrible.

The late recall was appalling. Not repeating the inspections seems weird - let's hope/assume Shimano knows why repetitions are not needed.

Glueing the parts is a great idea for saving weight and seems to work well for parts from earlier and later batches. Nevertheless, Shimano would probably be wise to explain the cause for the failures.

Looking at the photographs of broken cranks, it seems that a thorough visual inspection of the bonds could have avoided (almost) all of the worst failures (depending on the glue they used).

Hollow parts from lower groupsets (105, Ultegra left crank) are not affected (as they are not glued).

Yeah, machined hollows are sort of fineish - if design-engineered with care (inc. validation testing) - fine. The machining can at least be repeatably done to the same quality quite reliably. There's a lot of cranks with machined out hollowing.

Hollow cause they glued completely different shell parts together - no! Even if the engineering is to a high standard, epoxying things in production has a lot more scope for hidden quality issues. It's a much harder process to reliably repeat to a precise, high standard of quality. Maybe fine for cosmetic stuff, but I don't want that slightly higher variance in a high-stress part, with potential catastrophic safety issues.

No thanks.

Doesn't Shimano issue instructions on how the inspections are supposed to be done and what constitutes a pass or fail? If Shimano pays shops to do given checks in a given way and fail/pass the parts in accordance with given criteria, then a shopkeeper can hardly complain if he gets "banned" for doing something different (which I presume is what is happening here).

There is an inspection sheet, however they are limited in information and you can't see inside the cranks (where most failures actually start from). Without special equipment, or destroying the cranks in the process there is no guarantee that a passed crankset is actually safe, or how far away from failure.

Cranks have passed the inspection and subsequently failed shortly after, if that's not proof the inspections aren't fit for purpose then I don't know what is.

They do ,his claim that it's industry standard is a lie .It's him and all the You tube hero's he knows tgat made up their own set of rules.

Ah Vousden. Jerks gonna jerk. Everything he does is for YouTube views disguised as "being on the side of the consumer"

You may agree or disagree with the approach of Shimano to this issue. However this Bike Shop publicised that they were not following the process that they were taking the money for. Morally their approach may be correct and morally I'm sure they now feel a lot better not taking payments from Shimano under false pretences.

Your point is valid but at least partially mooted by the fact that these cranks should have been fully recalled by the manufacturer. Even cranks that have passed inspections have gone on to fail shortly afterwards. I have seen the entire video, and Paul's cohost and fellow Mapdec mechanic had a set of affected cranks which were one of the first they inspected under the programming. They initially passed them only for the cranks to fail a week later, luckily he came away unscathed. Since then Mapdec's policy was to send the cranks off for further inspection, citing customer was dissatisfied by the product not outright failing. Shimano replaced any and all cranks they received without inspection. That's on Shimano.

Yes it was stupid to have said "we no longer inspect" and this was also covered - as it was not actually outright true. It would have been more accurate to claim "we no longer pass" as "any that do not fail outright we will discuss with the customer who is inclined to disagree with a potential pass findings." It might still have led to a ban, however it would have avoided accidentally misleading anyone.

But the fact there is a LIST means that other LBSs have the same inspection policy, and have been prevented from returning affected cranks. We know nothing of this list - how many shops are on there, and whether any of them have public profiles in a similar manner. I suspect a number of these shops do not have a YT channel nor have been public about their inspection policy. That should be more concerning.

Add another spanner in the works: not mentioned here, Paul contacted a lawyer over Shimano's liability waiver following the incident as given above - and couldn't give a straight answer that it would hold up in court. Essentially, Shimano gave out a document to dealers stating that they, the manufacturer, hold full liability and that the dealers are exempt from any lawsuit or litigation regarding any set of cranks that fail following an inspection - however in UK courts as dealers are classed as professional individuals, they could still be found liable in court on the basis of neglect, declaring such document void. In other words, a shop could still be sued alongside Shimano if a set of cranks previously declared safe failed on somebody resulting in an injury or worse.

Shimano have, and still do, make some incredible and innovative products, but the handling of Crankgate falls far below what should be expected from a customer service standpoint. With the emergence of Chinese brands such as L-Twoo, Sensah and Wheeltop, Shimano have to do better to stay ahead of the emerging trend.

Are shops actually being prevented from returning cranks? What's preventing them returning the cranks independently of the "program", if they feel there are signs that something is wrong with them?

There is nothing preventing them from sending in a set of clearly failed cranks, per se, but Shimano, or in this case the UK distributor Madison, may not approve a replacement if it is not obvious there is a failure. Secondly there is a payment of £35 to cover the labour costs of the shop - who have taken their professional time to remove, clean and inspect the old cranks, filling in the form, sending them off, before fitting the new ones. The problem is that the going rate for labour charges is about £35/hour, and the sum of the active work involved in the process takes at least that long, so just covers that cost as if they were charging a customer to replace a crank. All the shops on the Banned list are no longer entitled to this payment meaning they do at least 1 hours work for nothing when they could be doing paid work for other customers. Considering many small independent bike shops are struggling, if they find themselves on the banned list they won't bother with accepting inspections.

You believe his friend sitting beside him ? I can tell you his " industry standard to send them all back " is a lie .

The fact that multiple shops have been blacklisted from the recall process suggests otherwise. It suggests multiple shops have adopted an automatic return policy for concern that the actions of Shimano not to issue a full recall leaves their legal position as professionals in an ambiguous state. At the end of the day the people being forced to make these decisions are the front line LBS mechanics - not structural engineers who have designed and built things using the construction method for these cranks. They do not have the knowledge or specialist equipment that could guarantee the safety of the affected cranks, and the mechanics who acknowledge this limitation have done the same as Vousen.

Yes, technically he broke Shimano's rules and thus gave them a reason to blacklist them. But the question posed by consumers and bike shops in general, as well as Mapdec is, are the rules fit for purpose?

The internet is awash with false conspiracy theories being masqueraded as critical thinking, and it has seriously impacted society's ability to do so efficiently on any subject.

In your own line of work, if your knowledge and expertise tells you something is wrong with the rules you have been instructed to follow, would you not question it? Would you not look to mitigate or change things? Especially if somebody else's health, wellbeing or worse life was at risk?

I'm in the bike trade Matt ,and yes I would question it .I wouldn't just make up my own rules and call it " industry norm " like he's done here .

That's why he got removed ,he didn't question anything ,he gave Shimano no option after admitting what he does. He wanted Madison to do an inspection he was already paid to do

Pages